Key Advantages of SLS

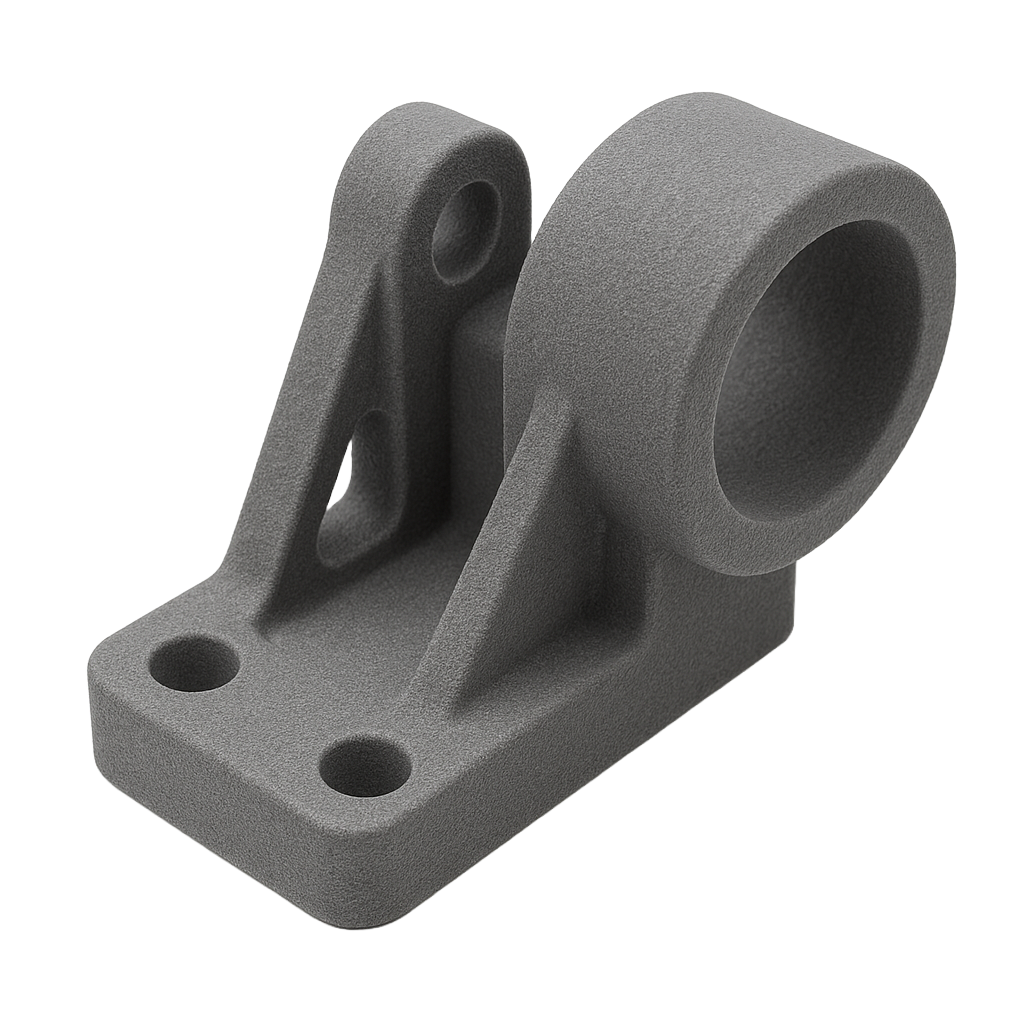

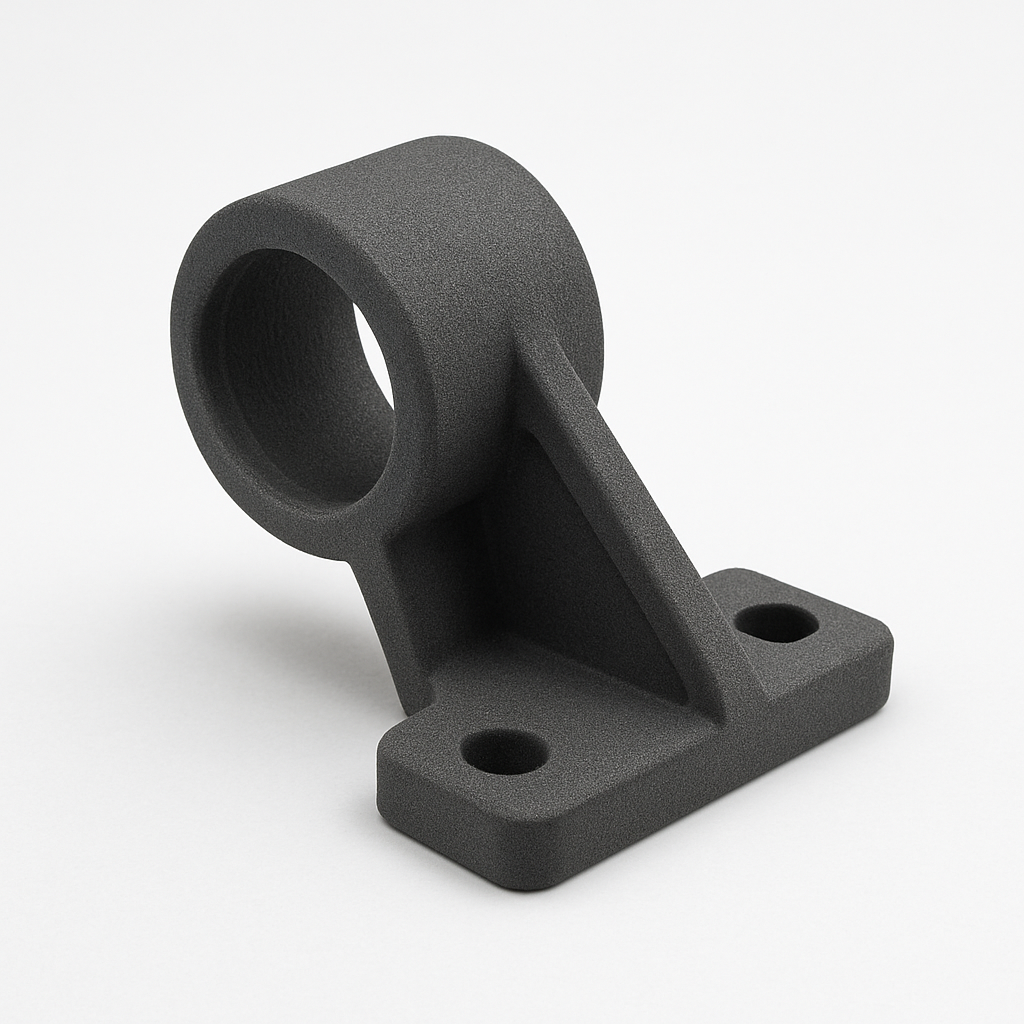

Functional, Durable

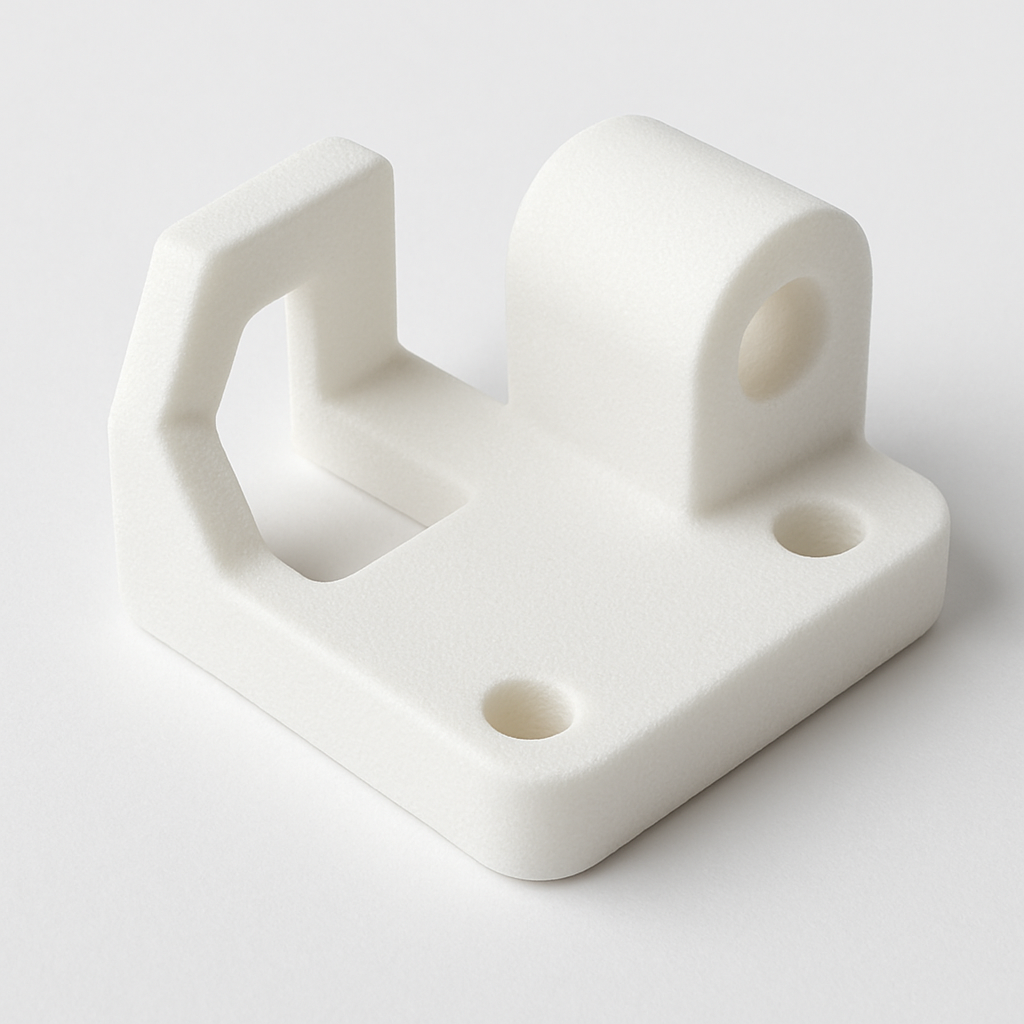

Parts

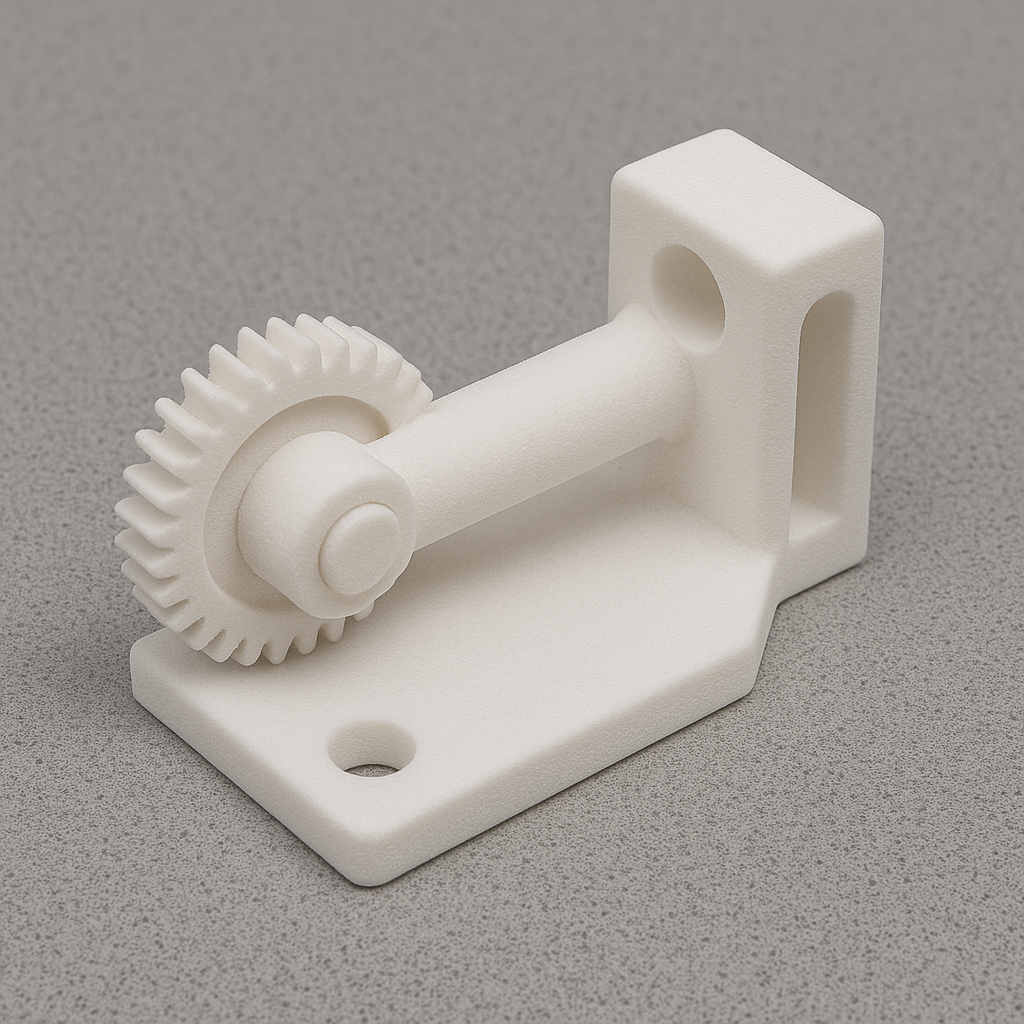

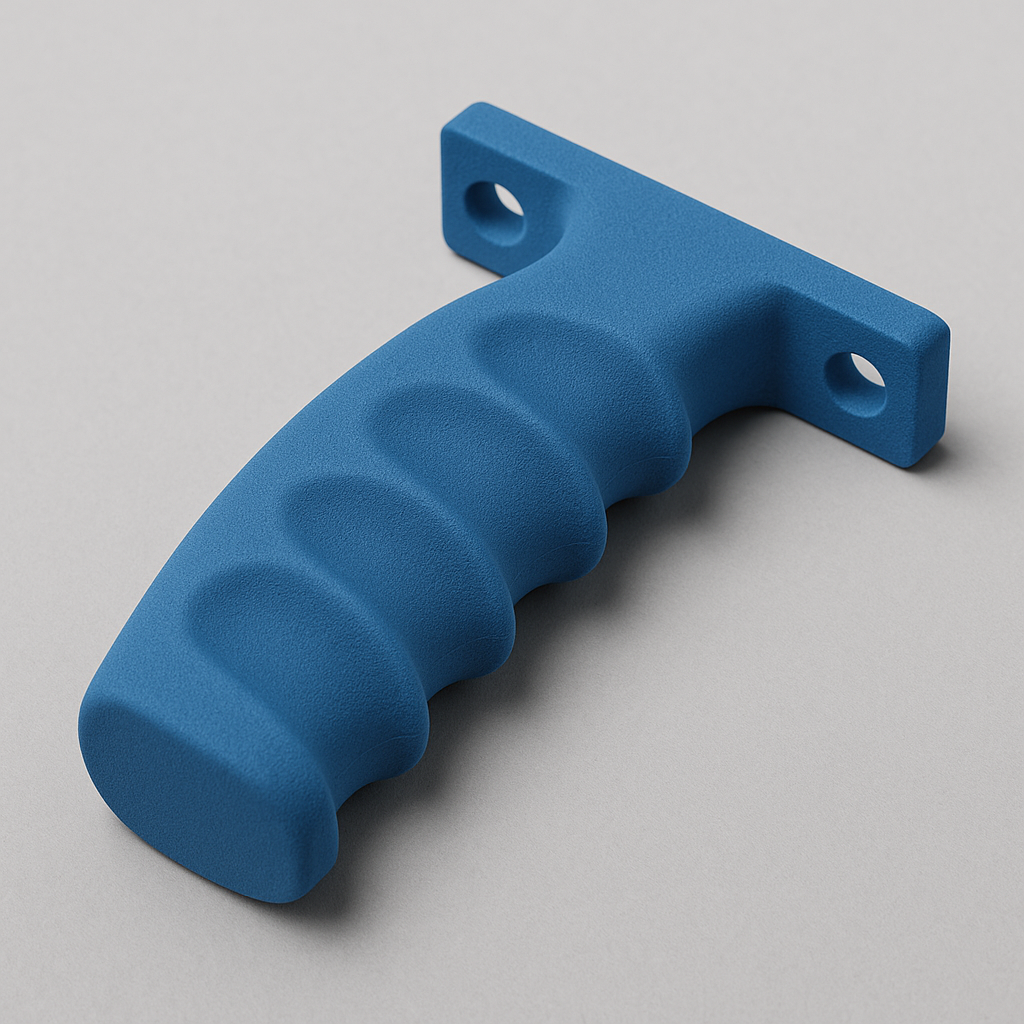

SLS-printed parts are tough, chemically resistant, and ideal for real-world use in demanding environments.

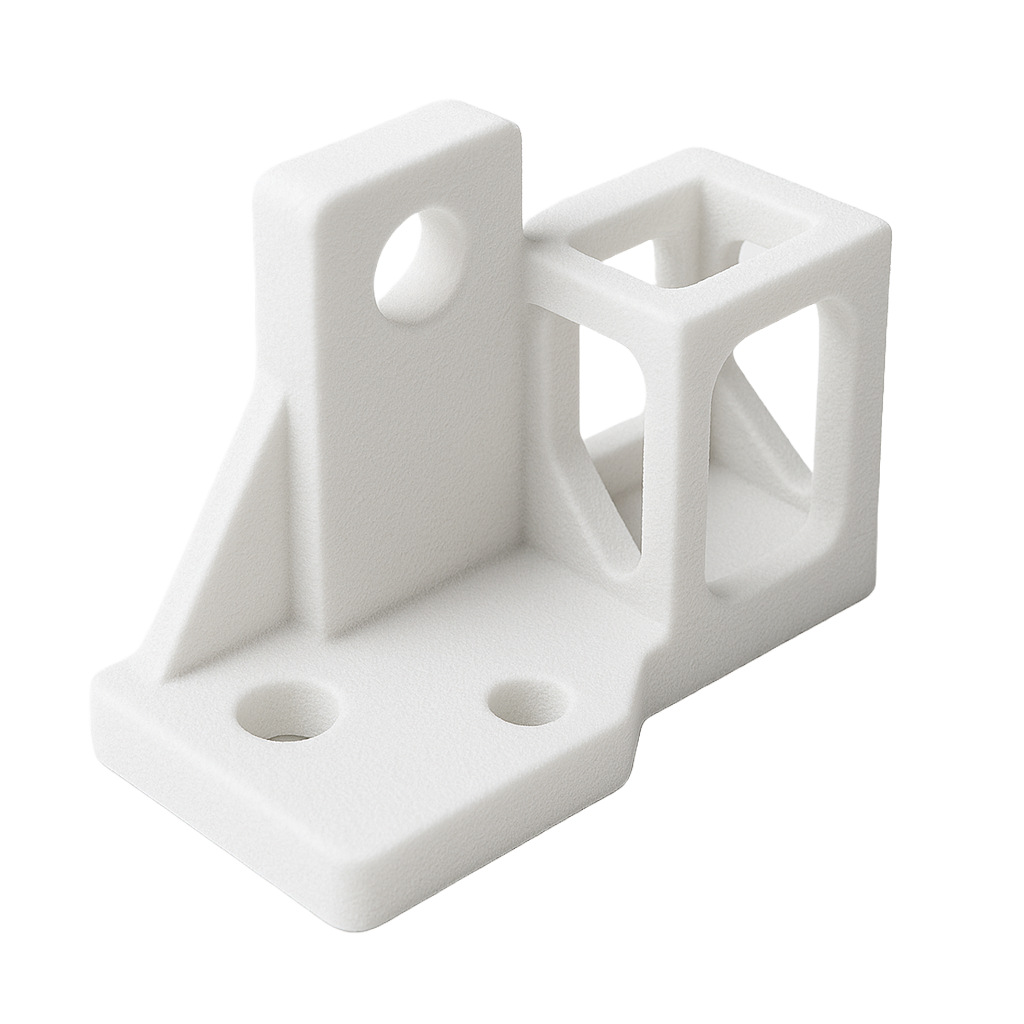

Complex Geometries, No

Supports

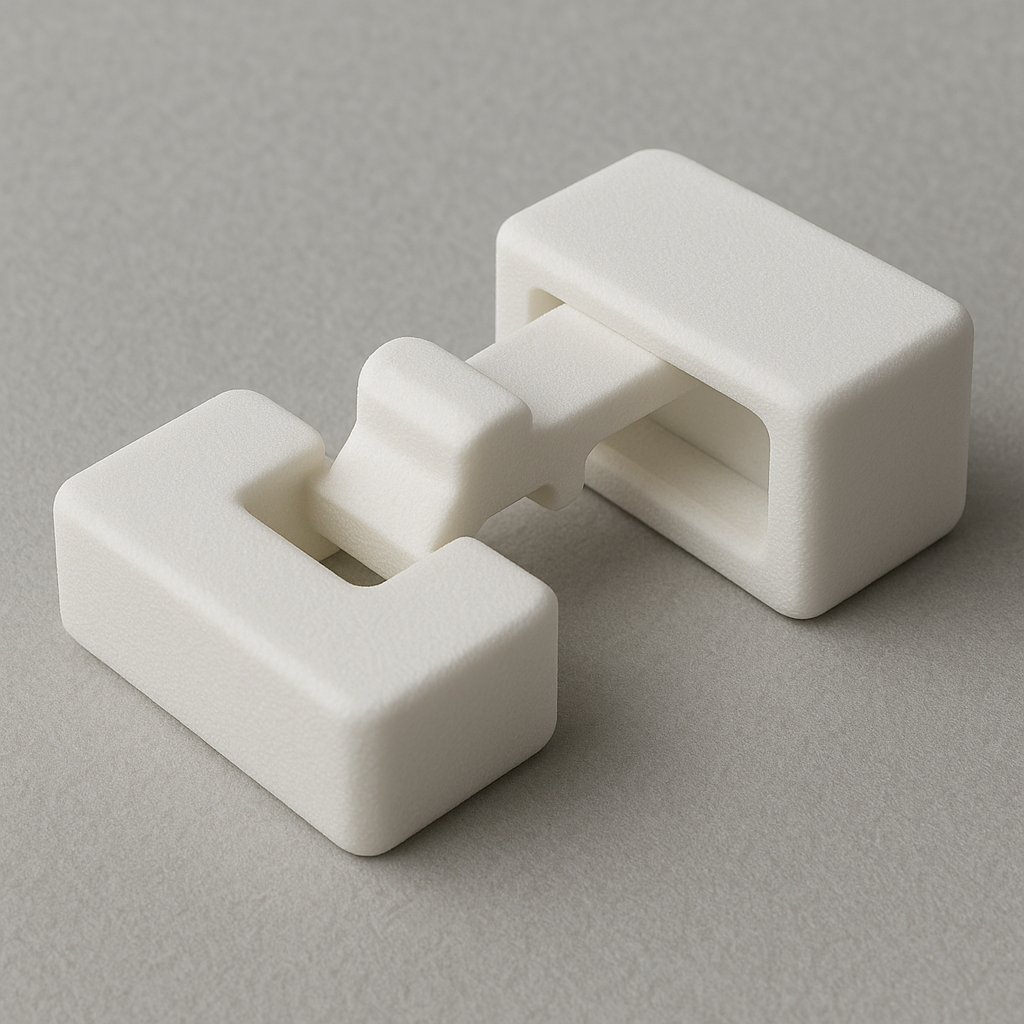

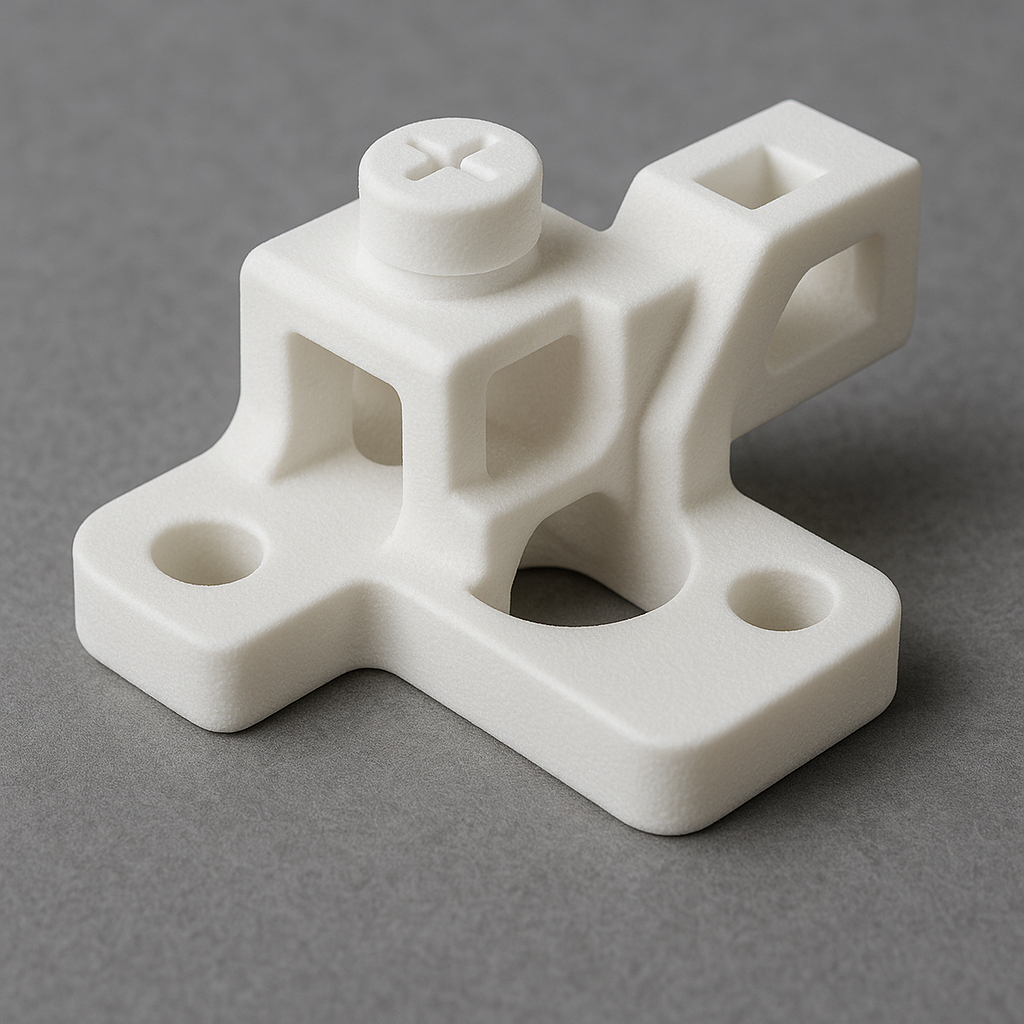

Print moving assemblies, lattice structures, and nested components in a single build with no support cleanup.

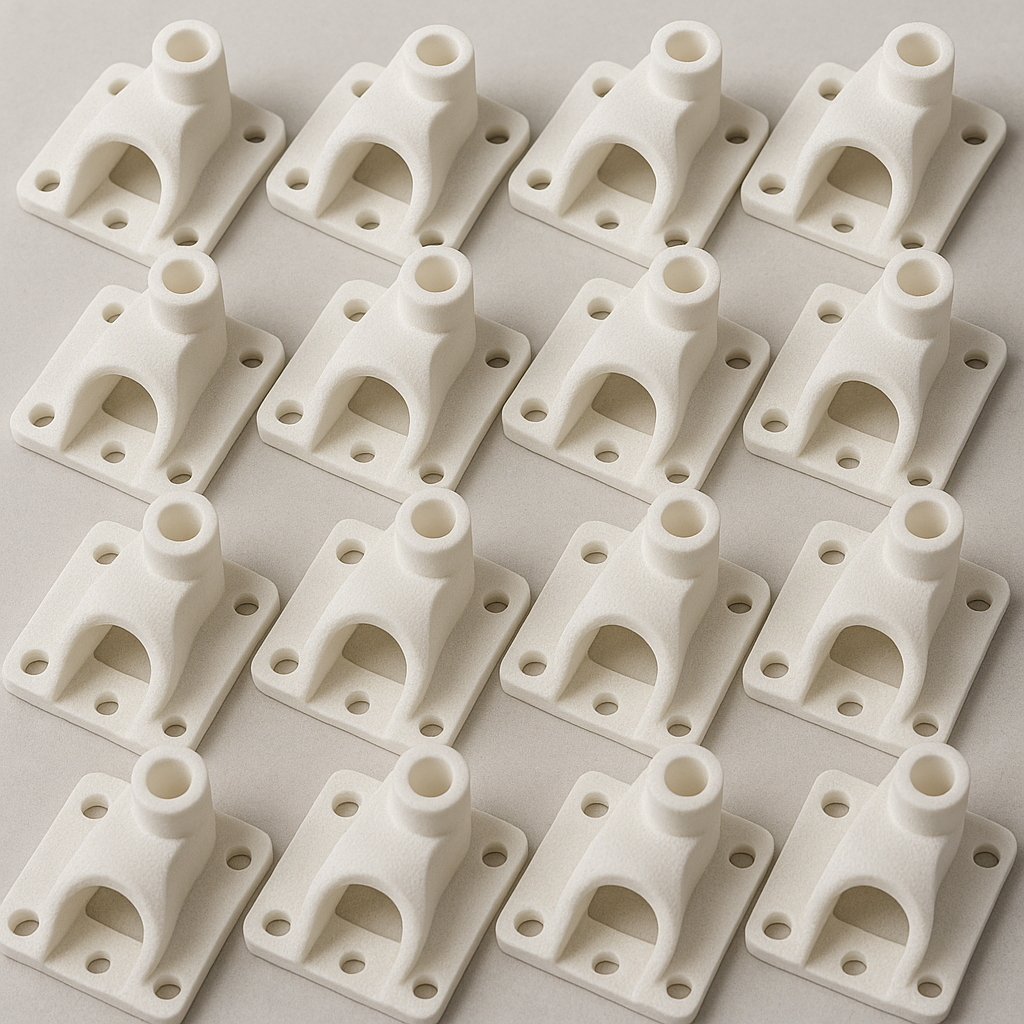

High Accuracy &

Repeatability

Tight tolerances and consistent output across small batches and large runs.