Advantages of SLA Technology

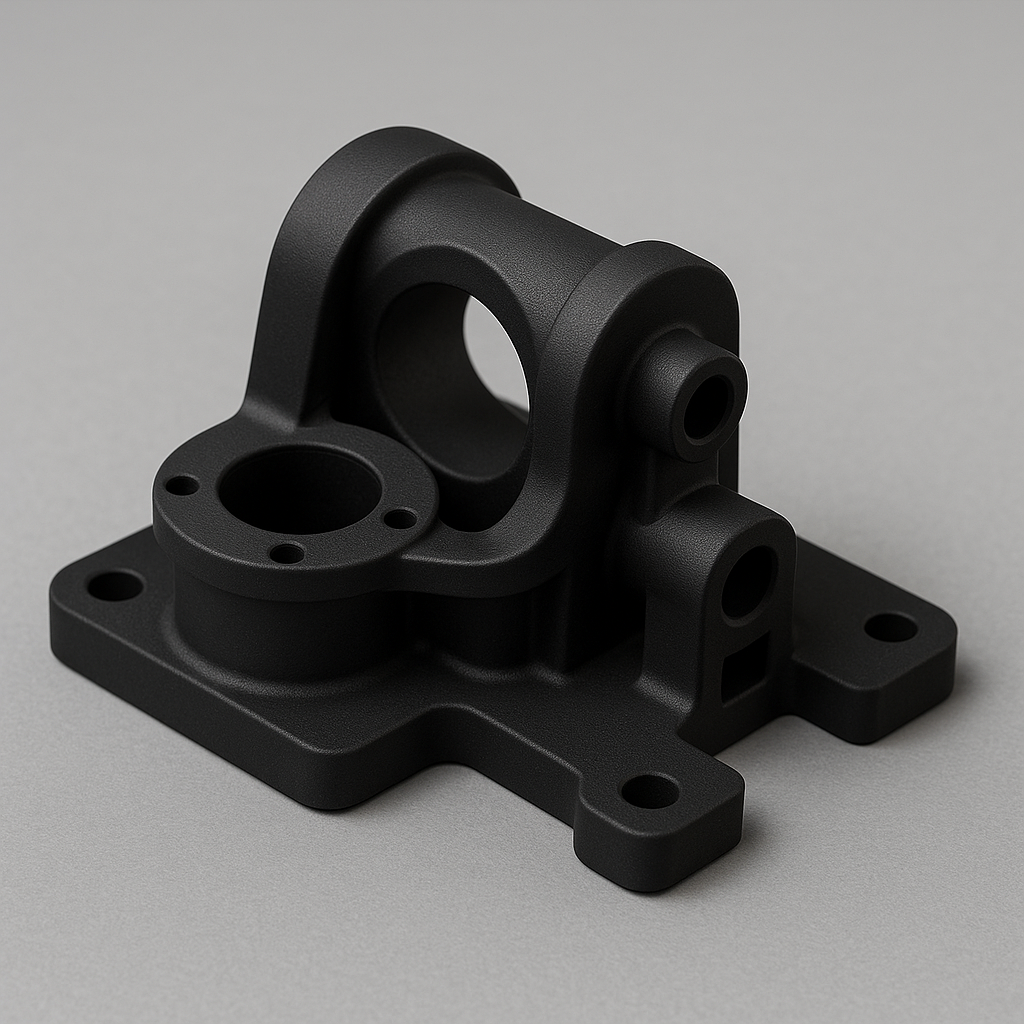

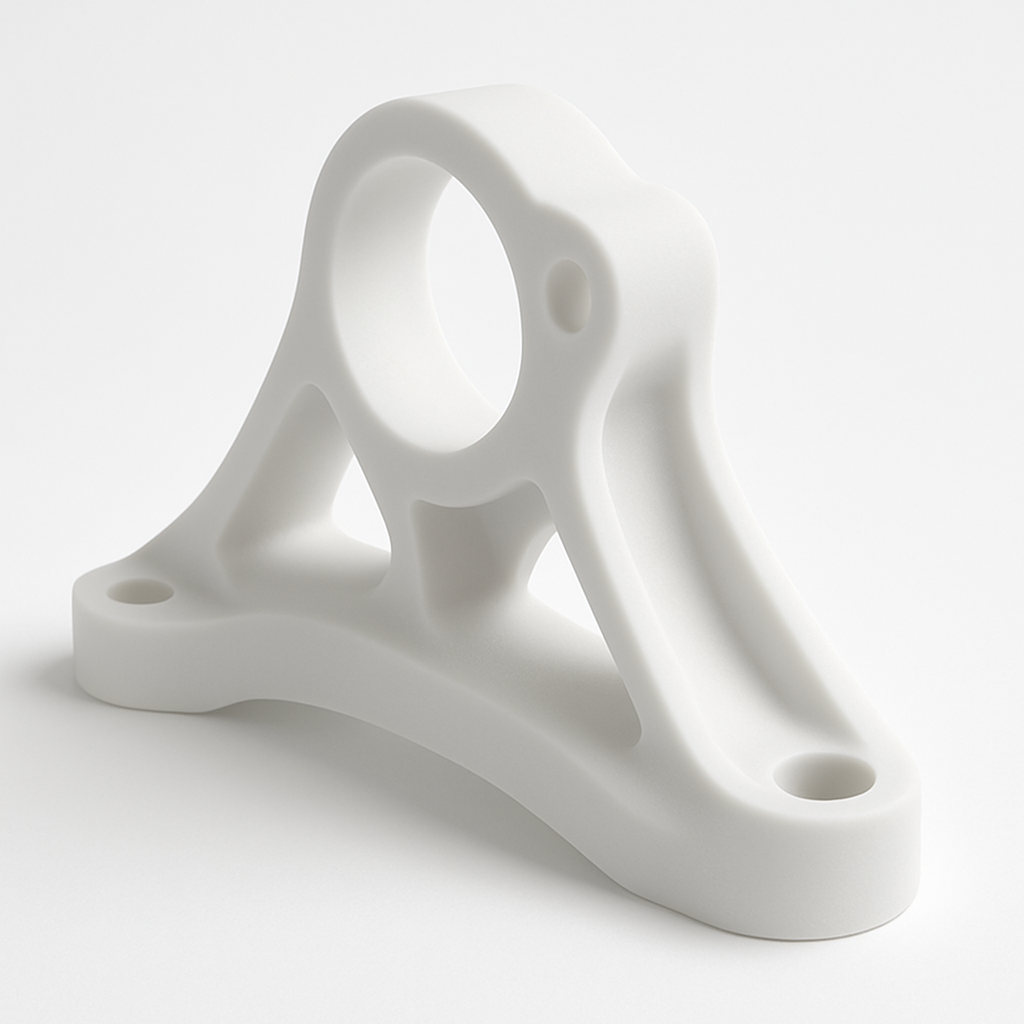

Superior Surface

Finish

Parts printed with SLA have a smooth, almost glass-like surface straight out of the printer—ideal for visual and cosmetic prototypes.

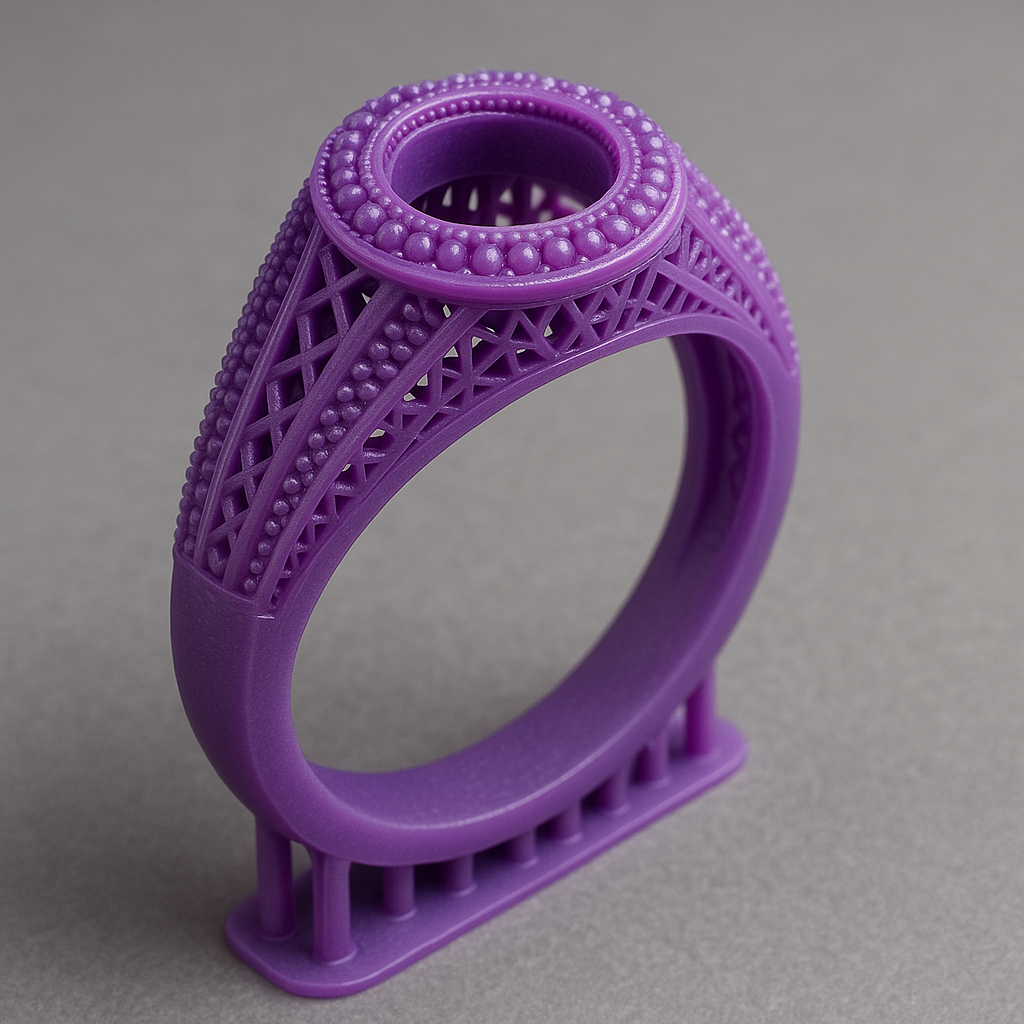

Exceptional Detail and

Accuracy

Achieve sharp corners, thin walls, and intricate textures with layer

resolutions as

fine as 25 microns.

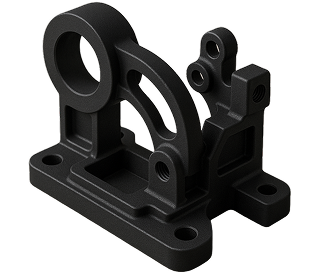

Ideal for Mold Making

and Casting

SLA is perfect for master patterns used in silicone molding or investment casting.