Advantages of FDM

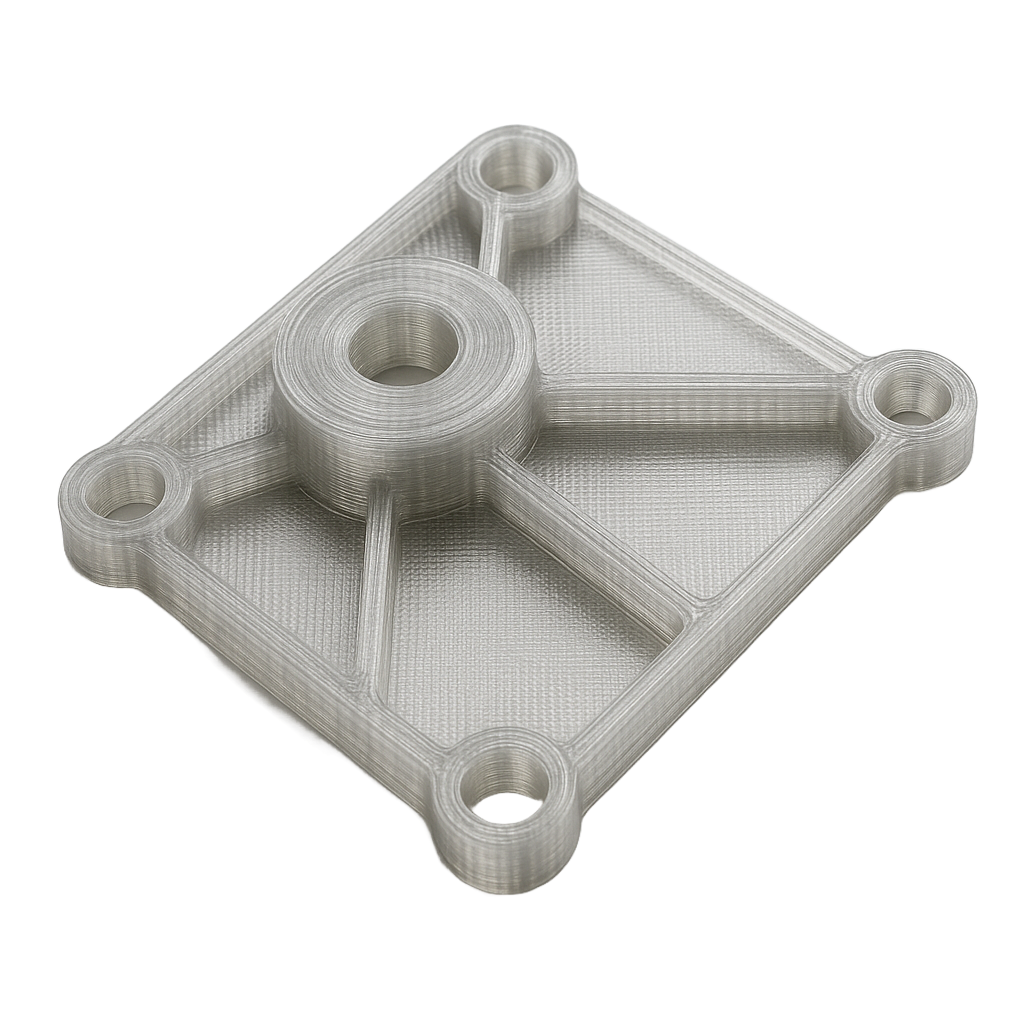

Cost-Effective

Prototyping

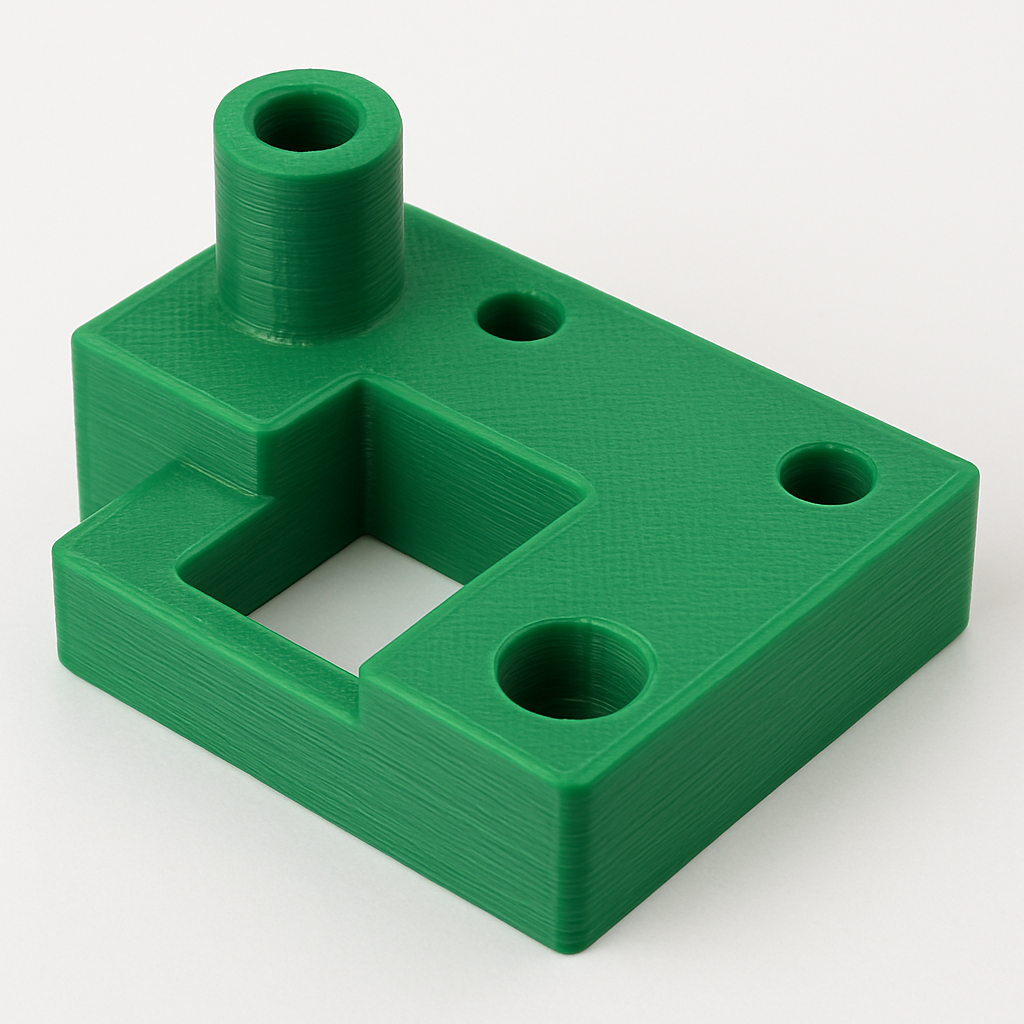

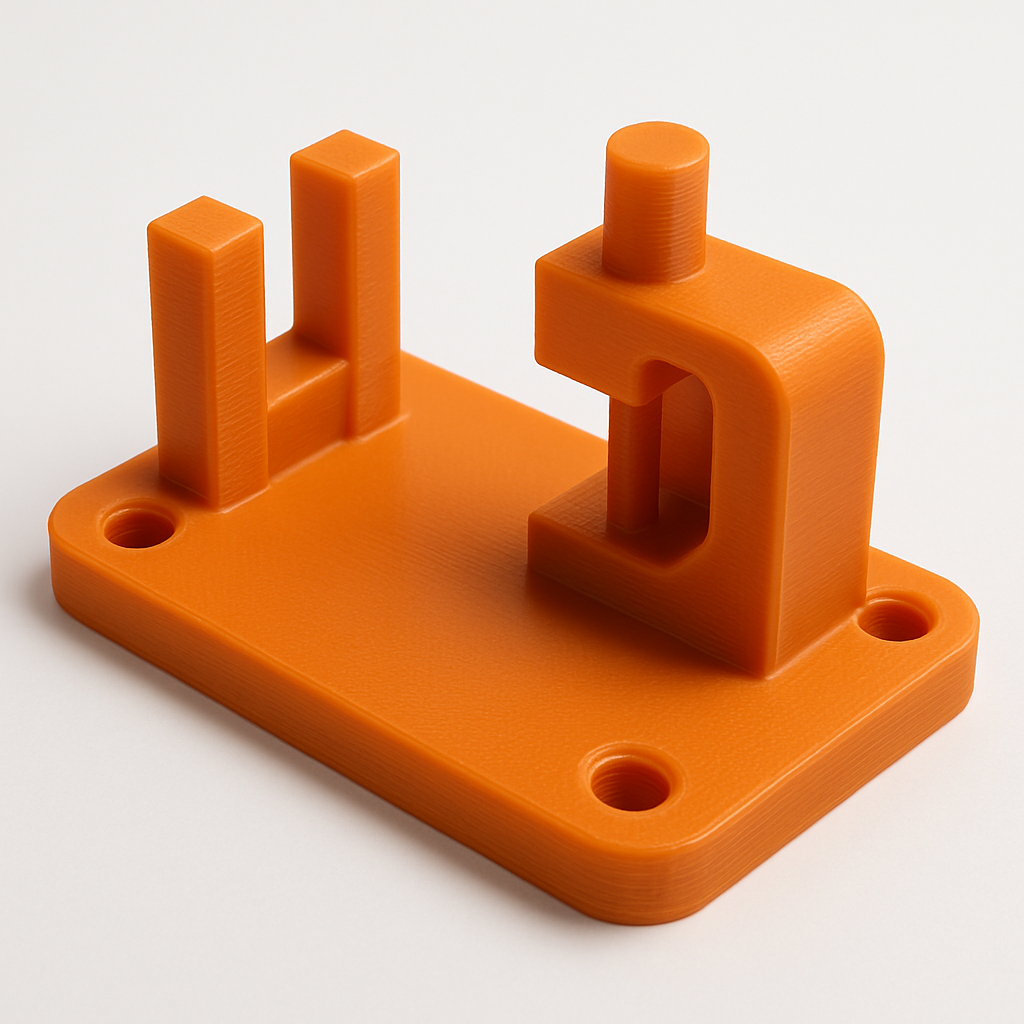

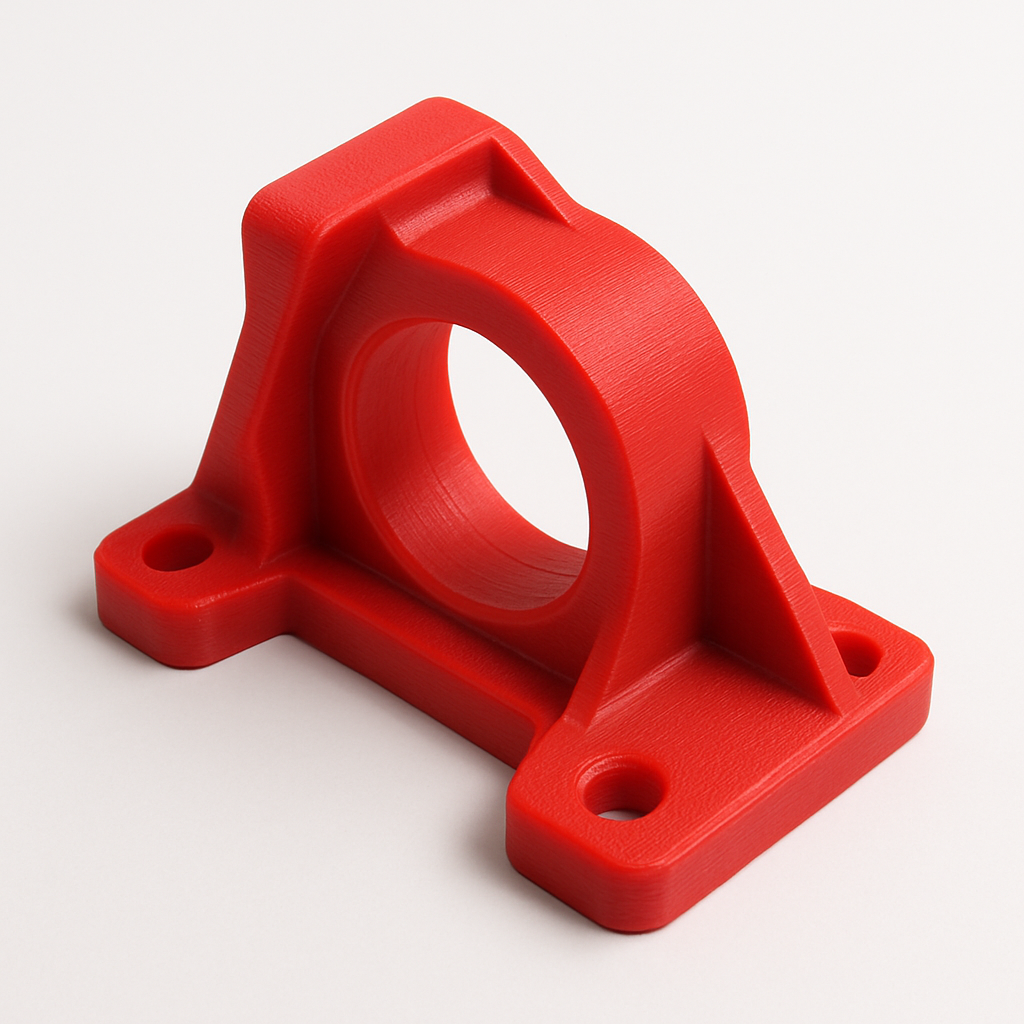

FDM offers one of the lowest cost-per-part options for developing prototypes, jigs, and fixtures.

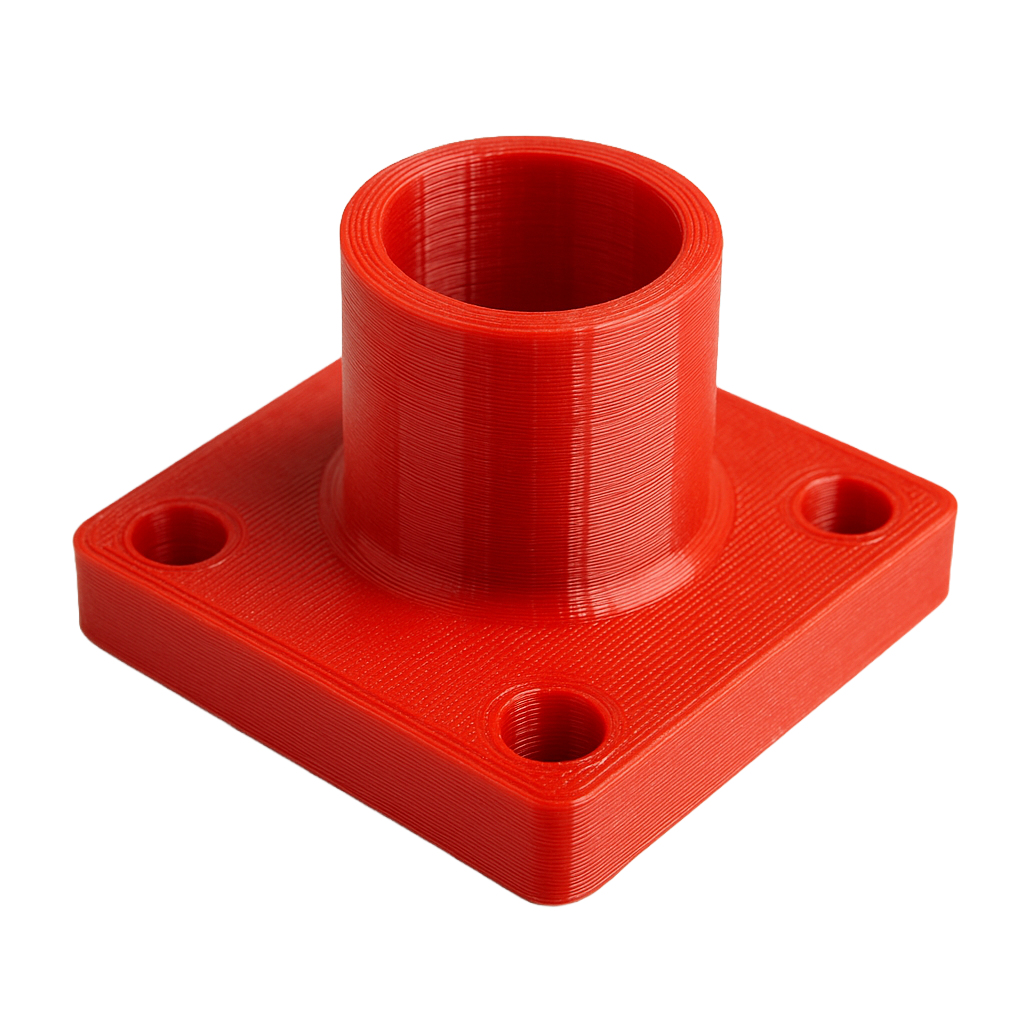

Broad Material

Compatibility

Choose from standard, engineering, and high-performance thermoplastics including ABS, PLA, PETG, PC, Nylon, ULTEM™, and carbon fiber composites.

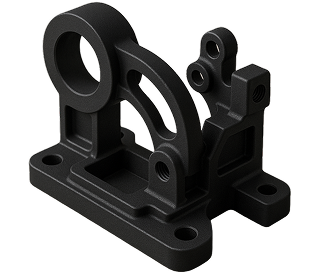

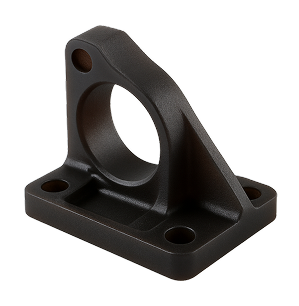

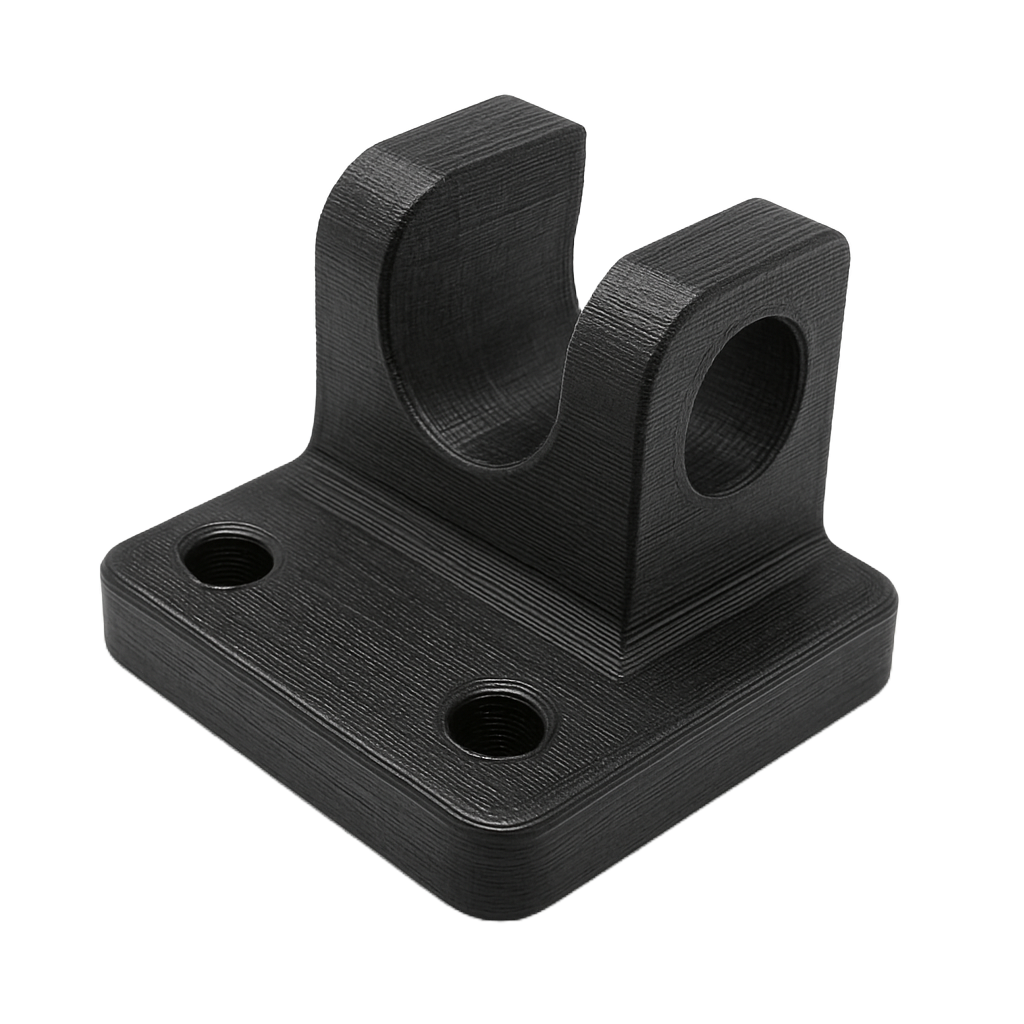

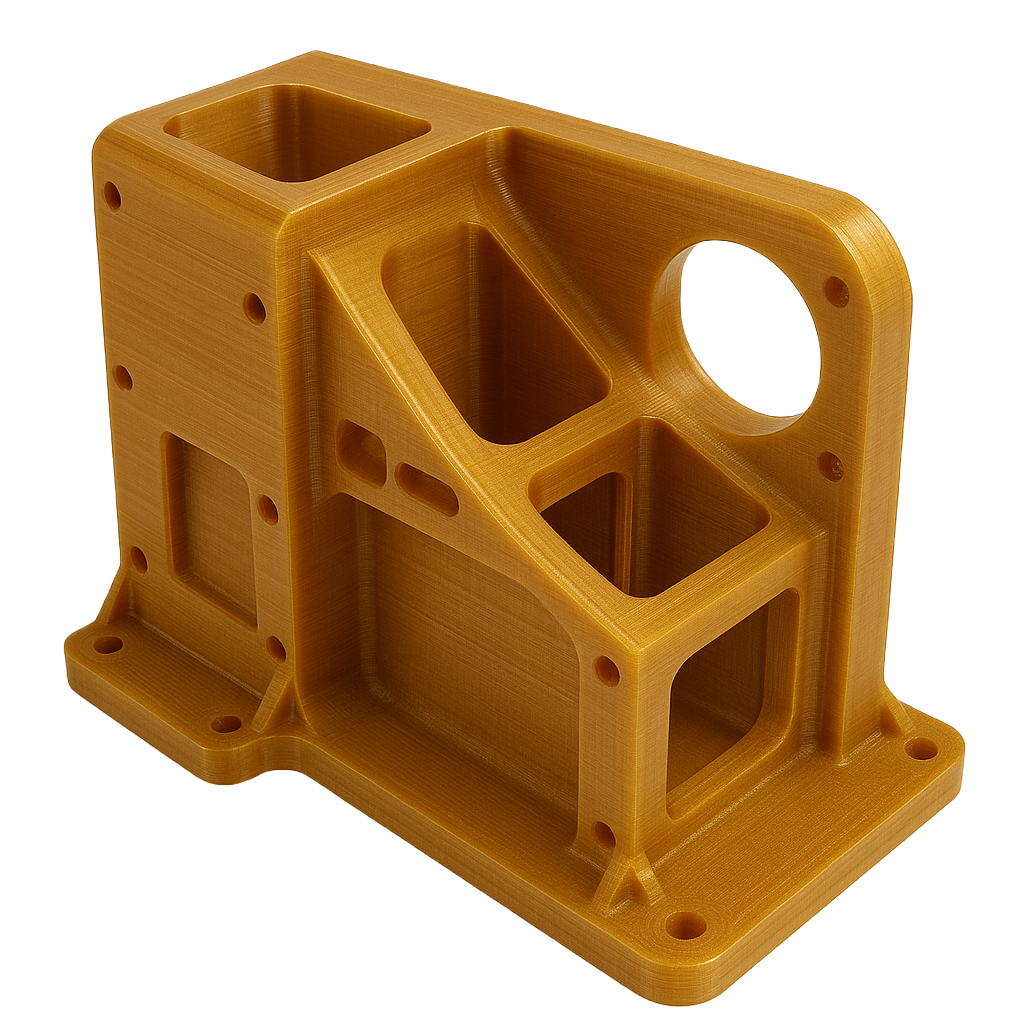

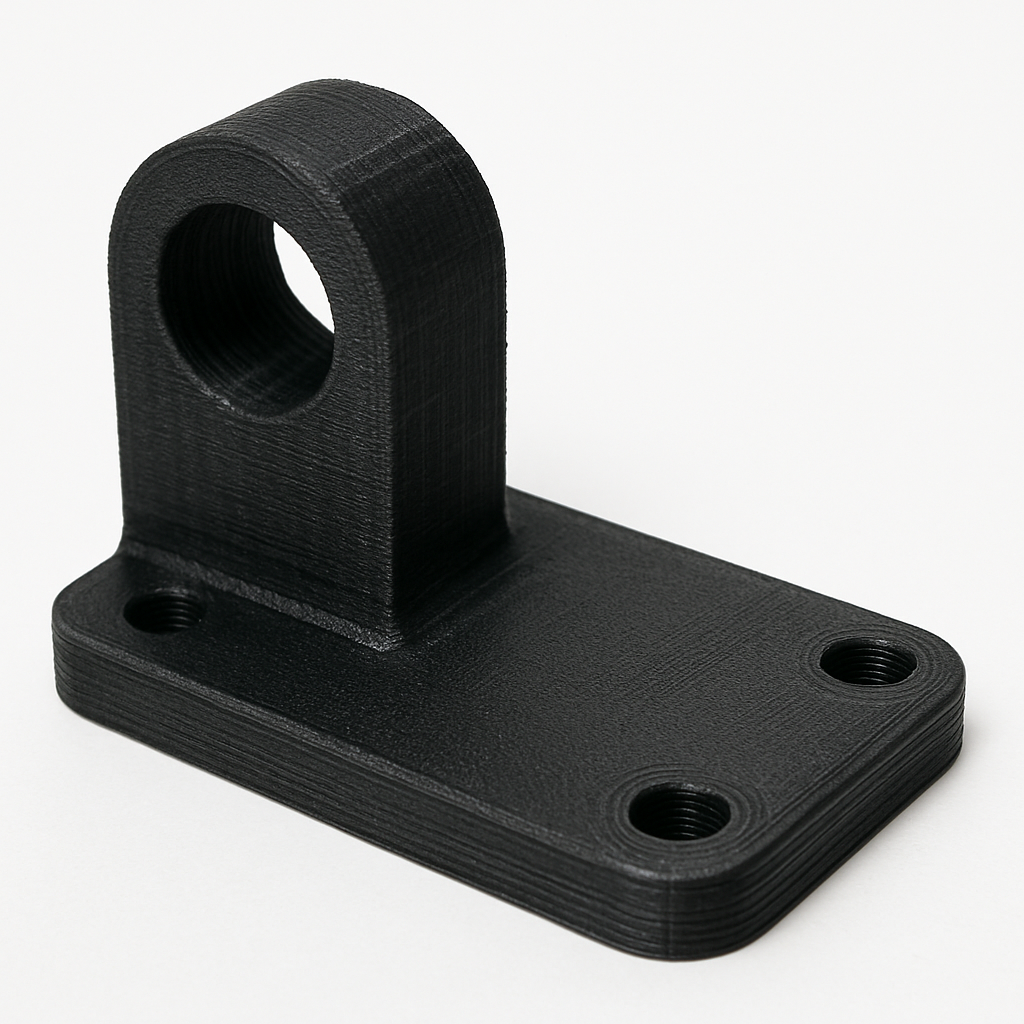

Strong, Functional

Parts

FDM printers are known for their speed and simplicity, making them ideal for quick iterations and tight deadlines.