Key Advantages of PolyJet Technology

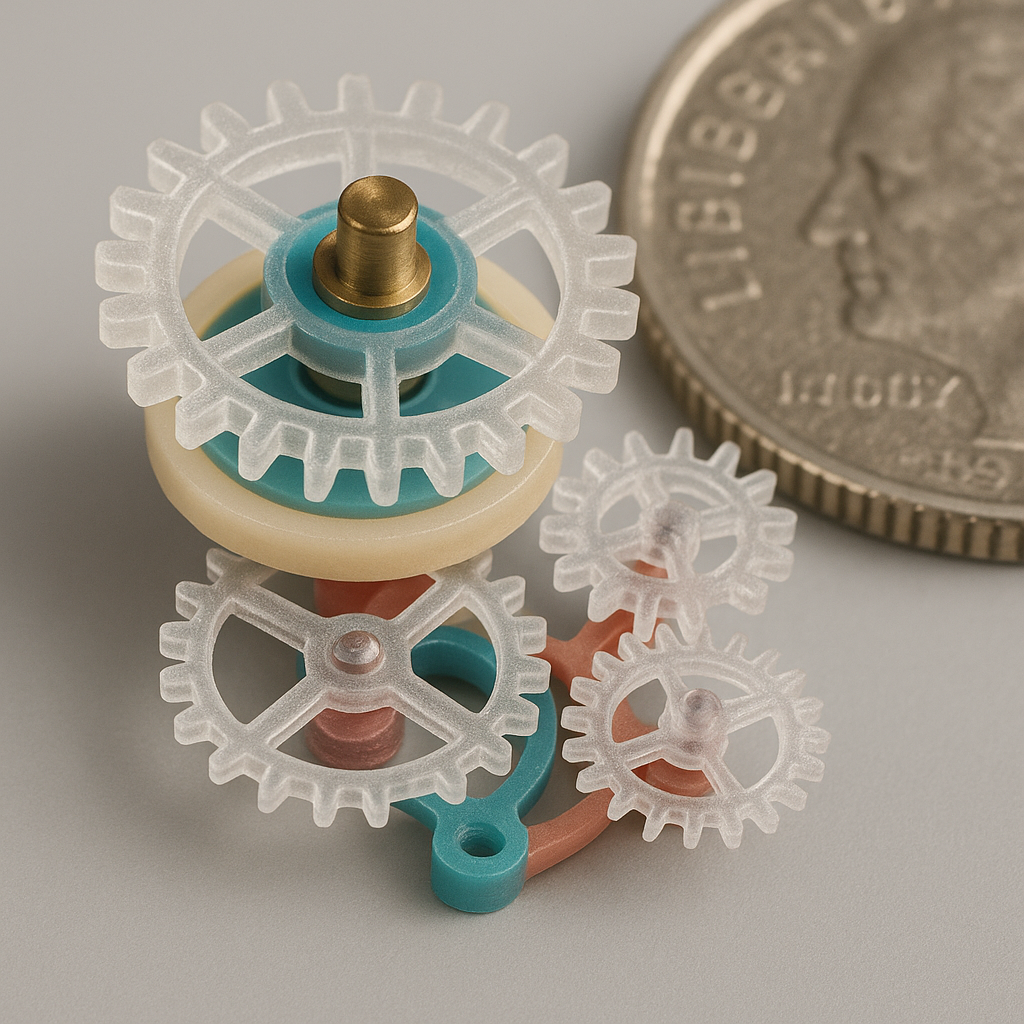

Exceptional Resolution and

Surface Quality

Prints with layer heights as fine as 16 microns—perfect for smooth surfaces, small features, and high aesthetic value.

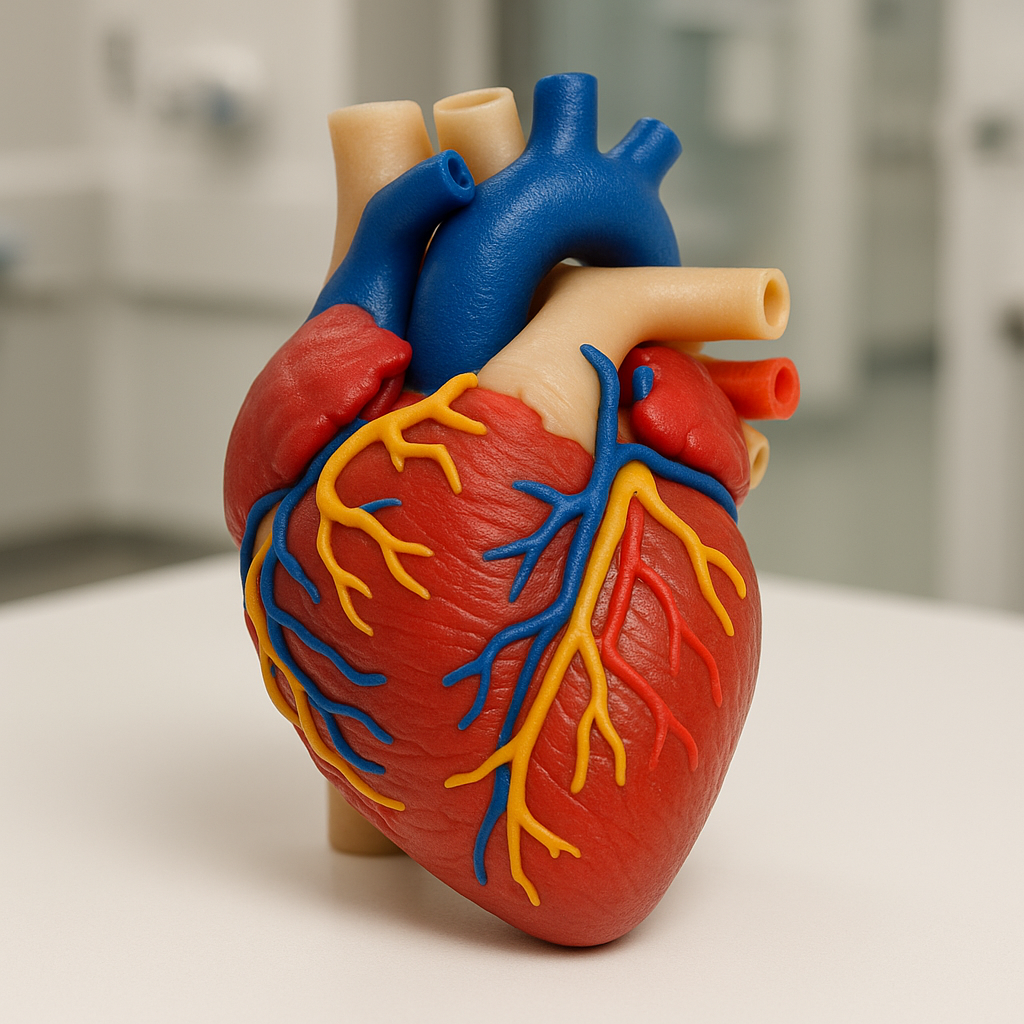

Multi-Material

Printing

Combine rigid, flexible, transparent, and colored materials in one seamless part for realistic prototypes and functional designs.

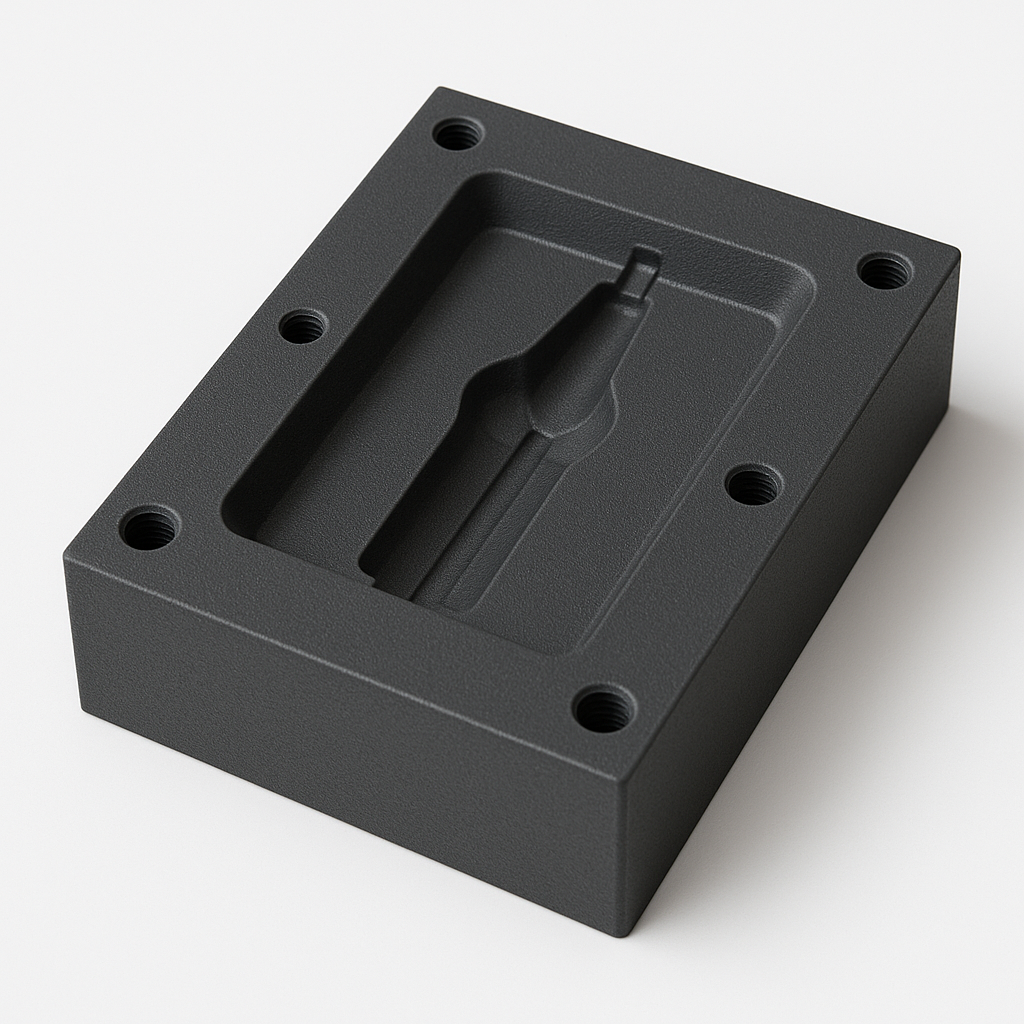

Color and Texture

Simulation

Replicate realistic product finishes, labels, buttons, and even skin-like textures for lifelike visual and tactile results.