Advantages of Binder Jetting

Advantages of Binder Jetting

Unmatched Throughput

Produce thousands of parts per day—ideal for mass production and batch manufacturing.

Cost-Efficient Metal Parts

Lower per-unit cost compared to laser-based metal printing systems due to faster build rates and minimal waste.

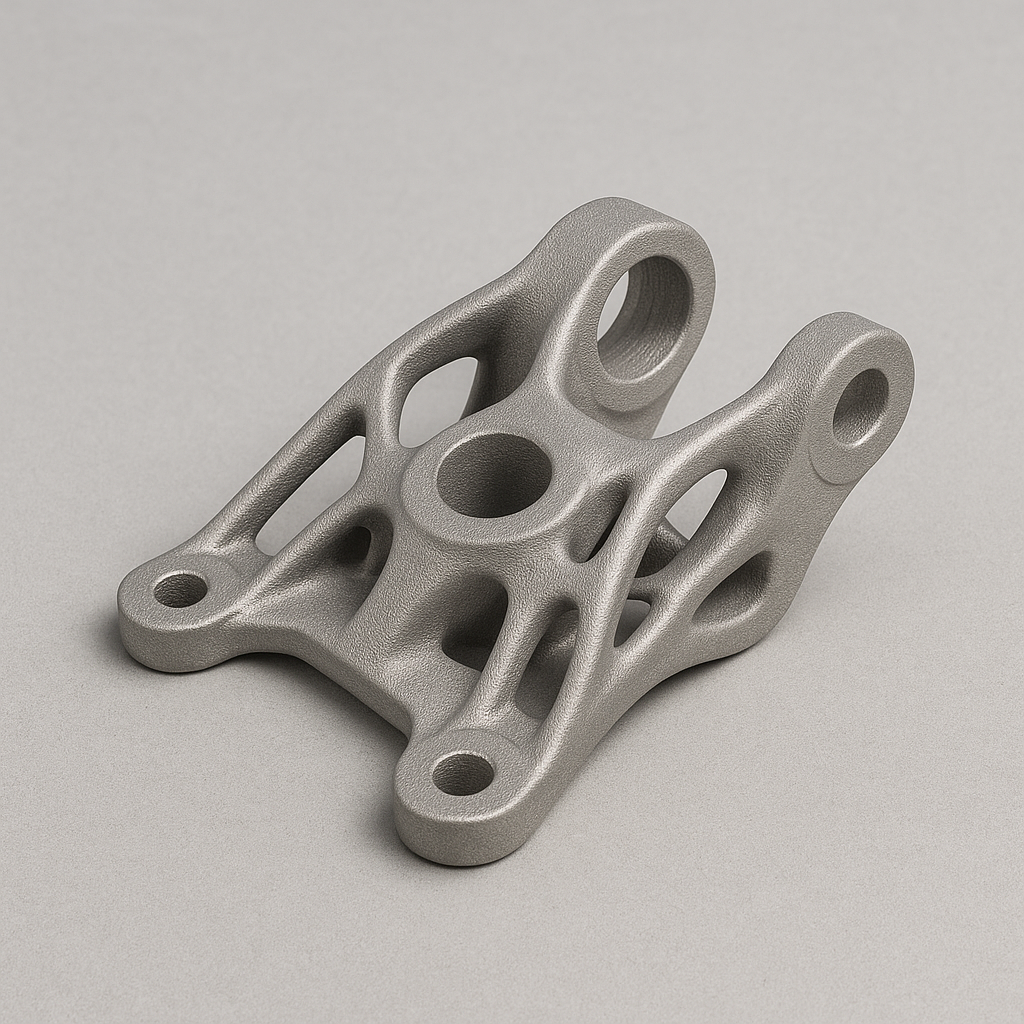

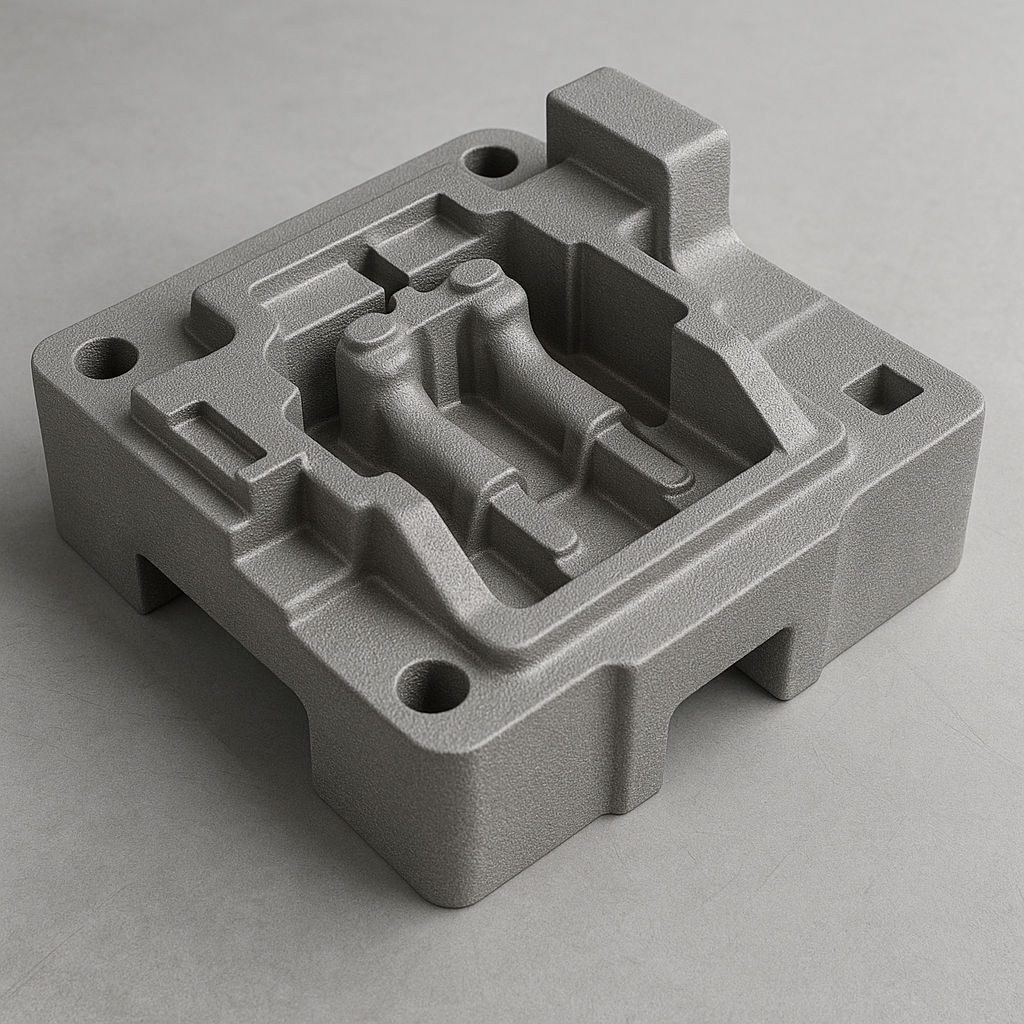

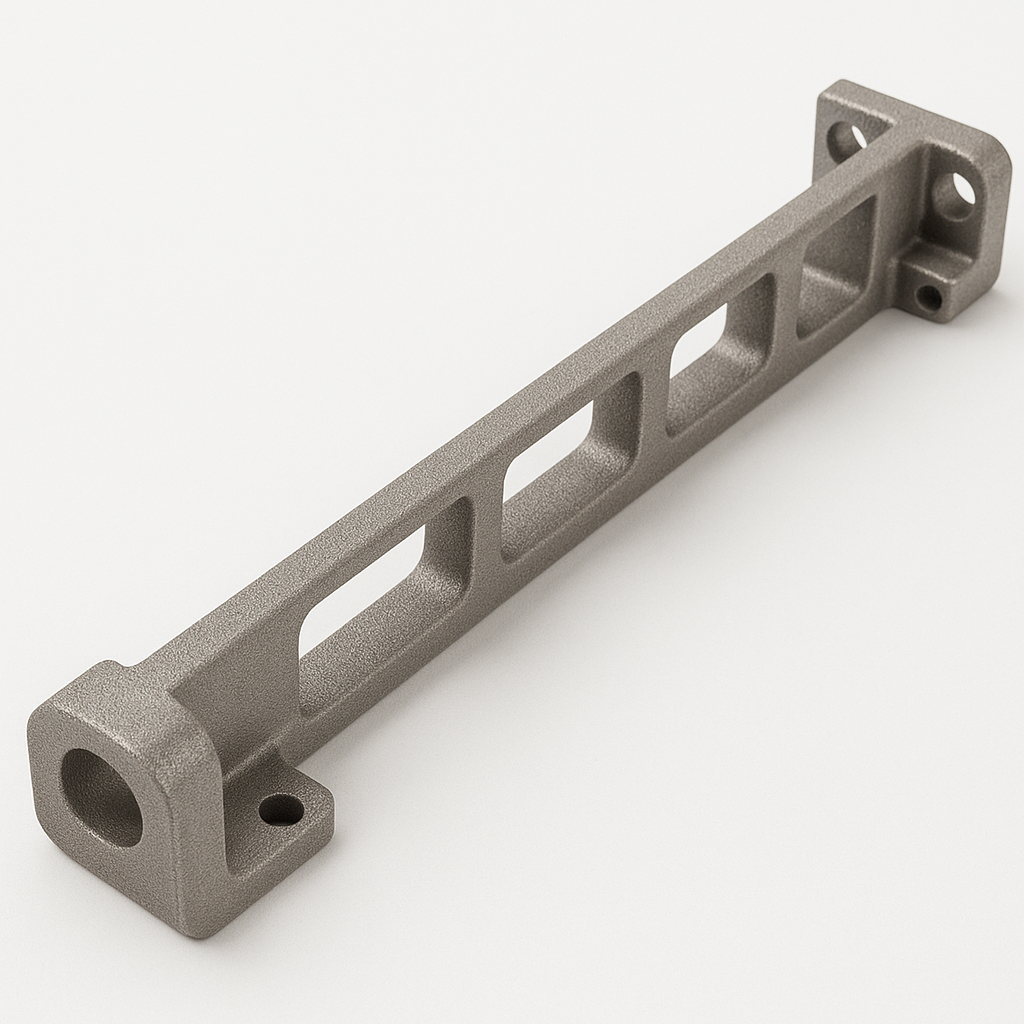

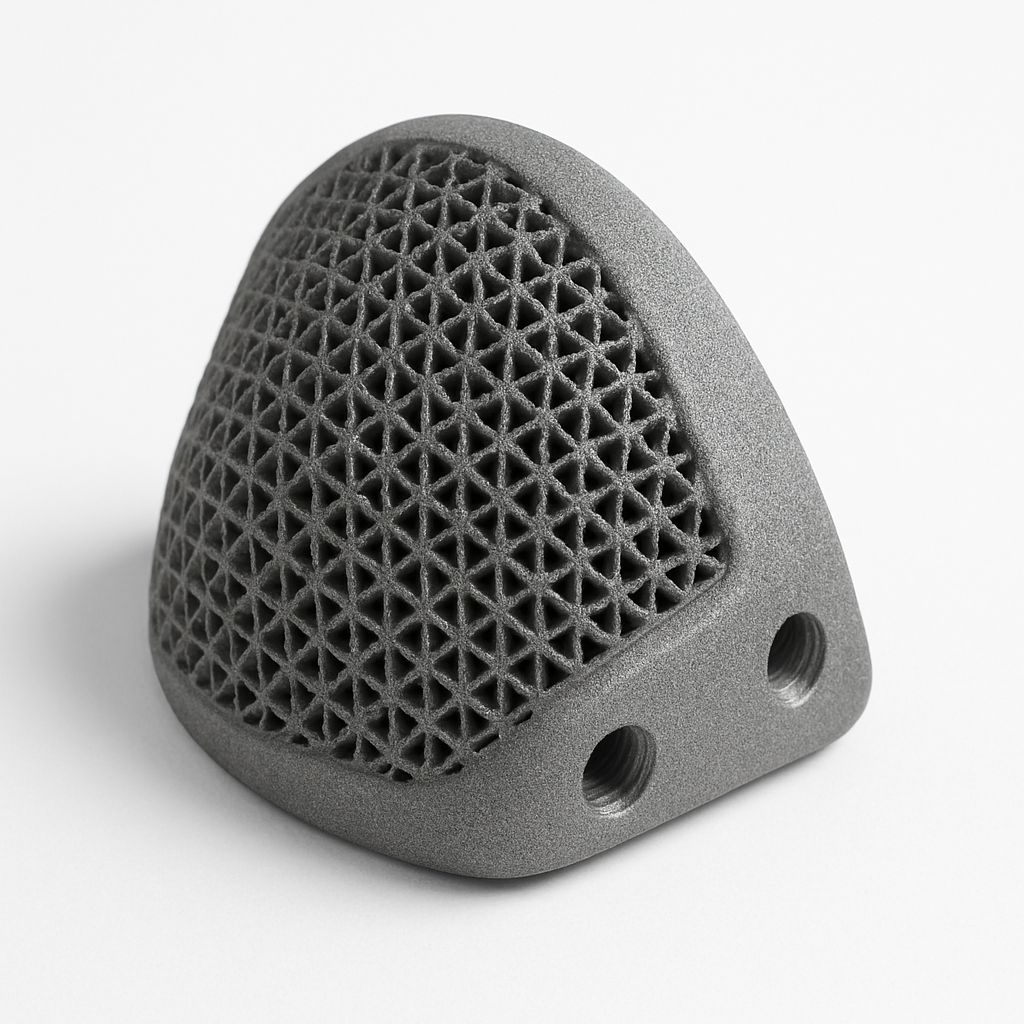

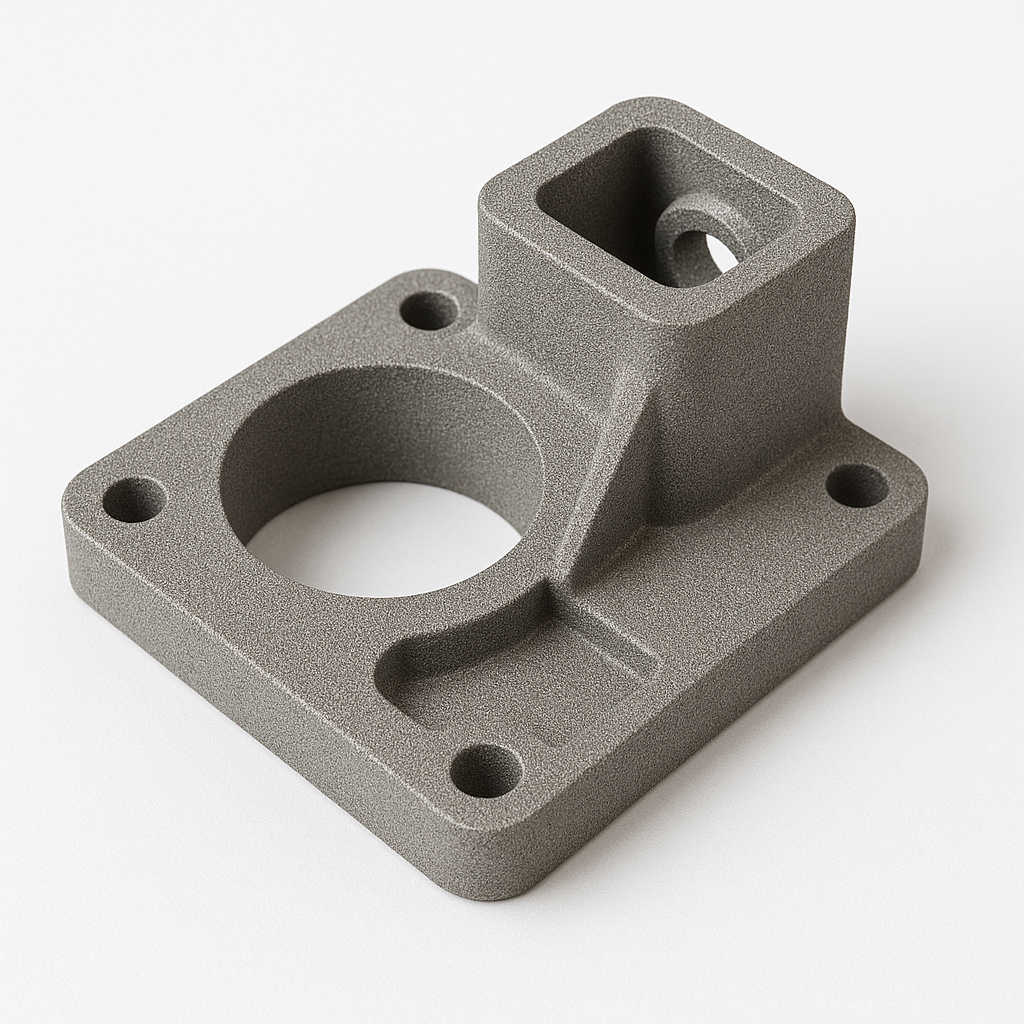

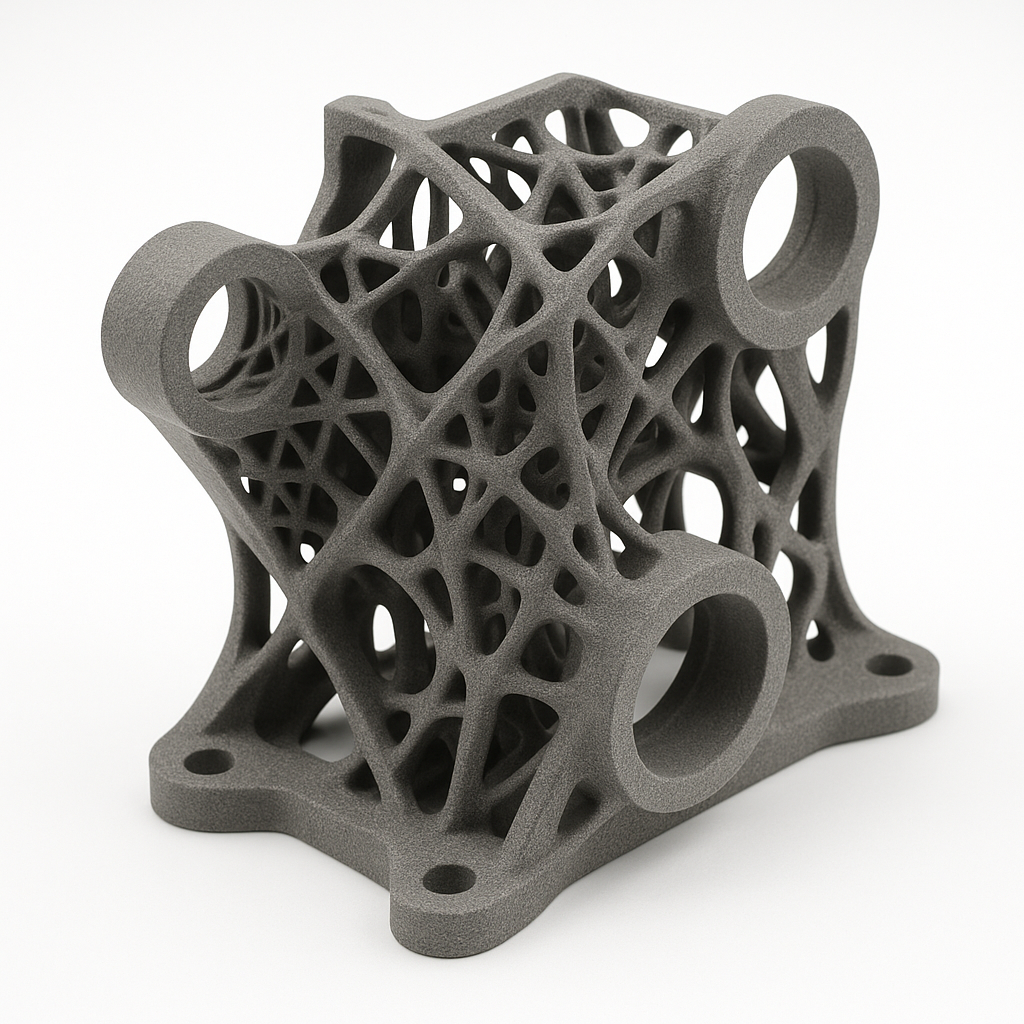

Design Freedom

Create complex internal geometries, thin walls, and lattice structures without support material.