Key Advantages of DMLS

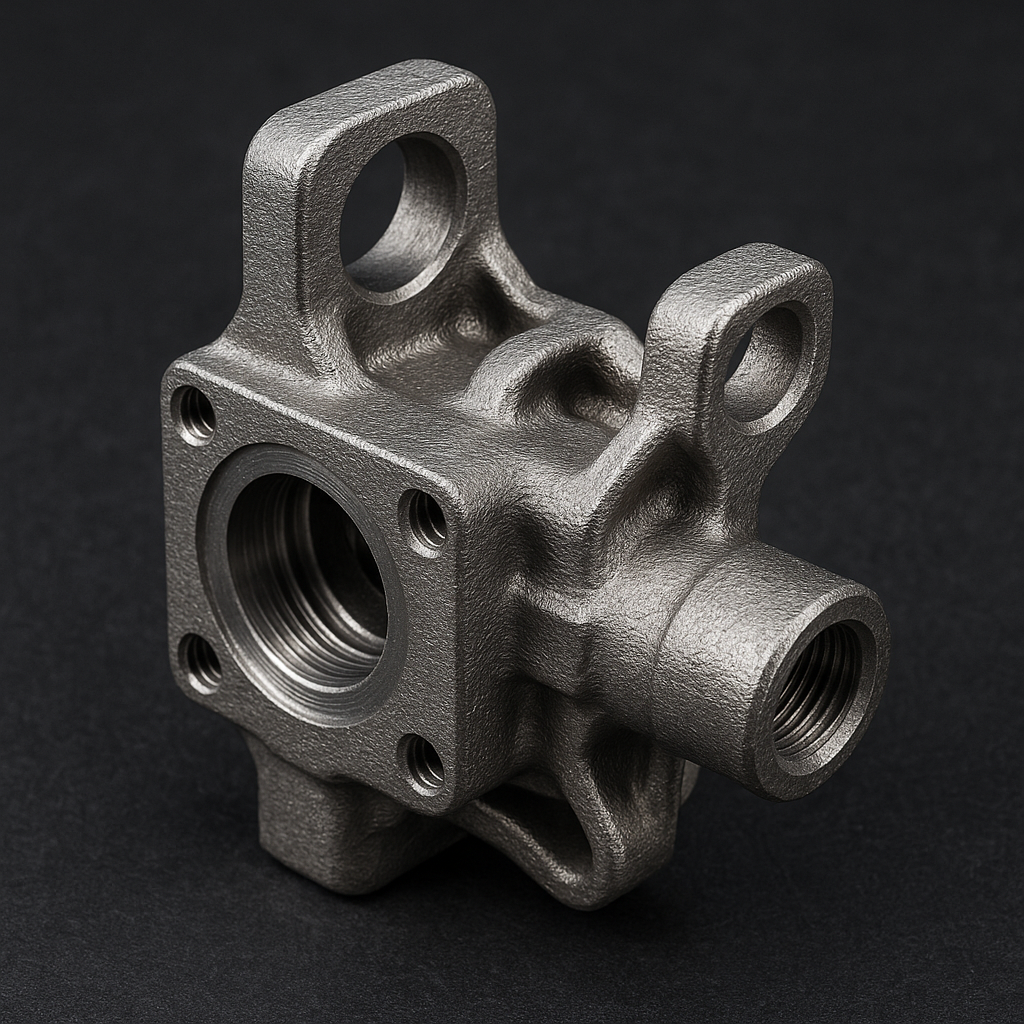

Fully Dense Metal

Parts

Parts produced via DMLS exhibit mechanical properties comparable to (or better than) traditionally manufactured parts.

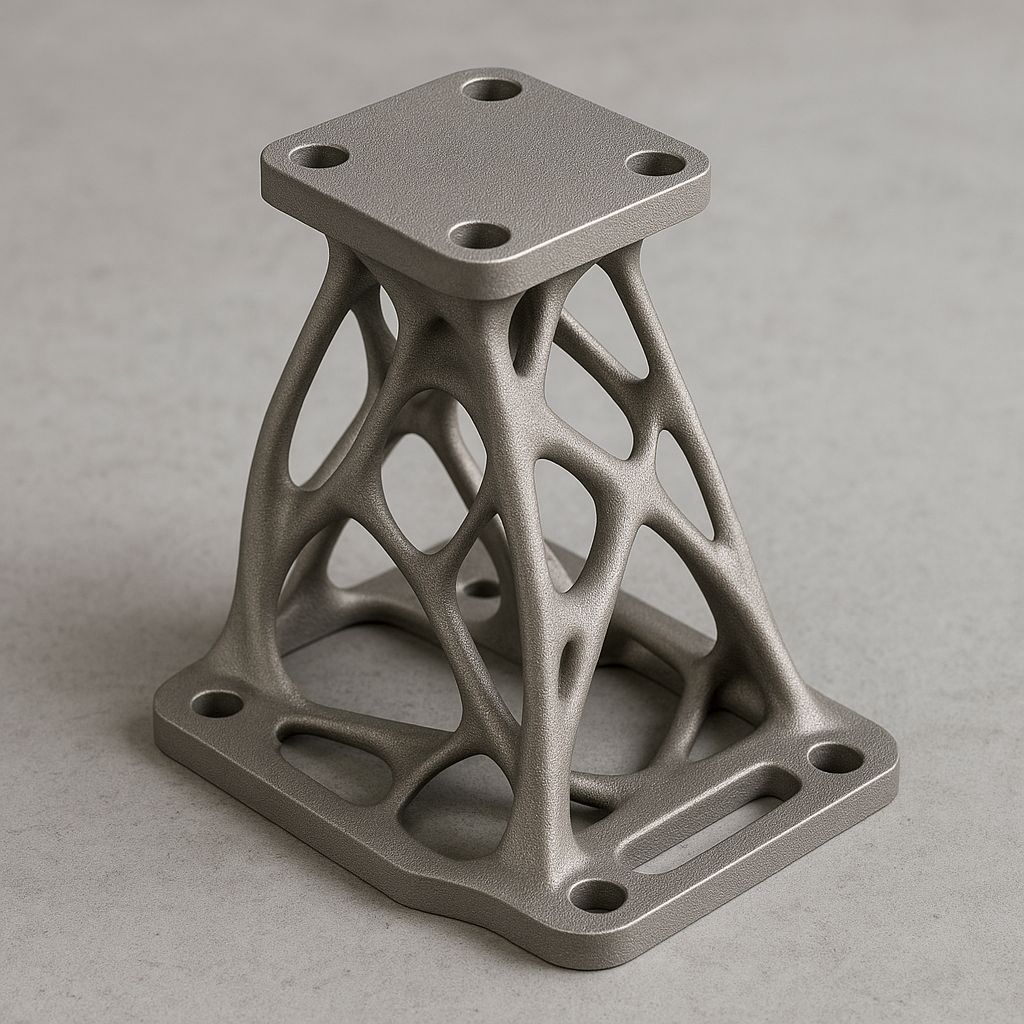

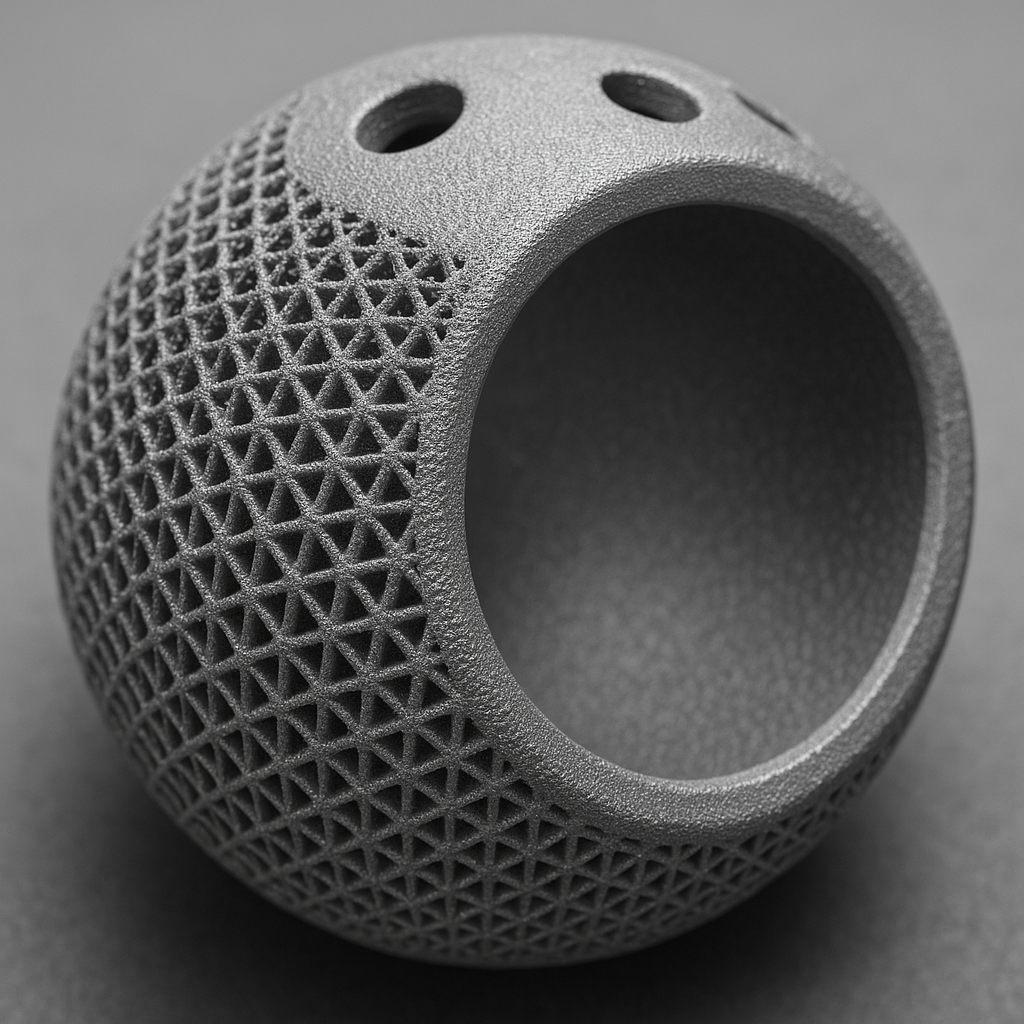

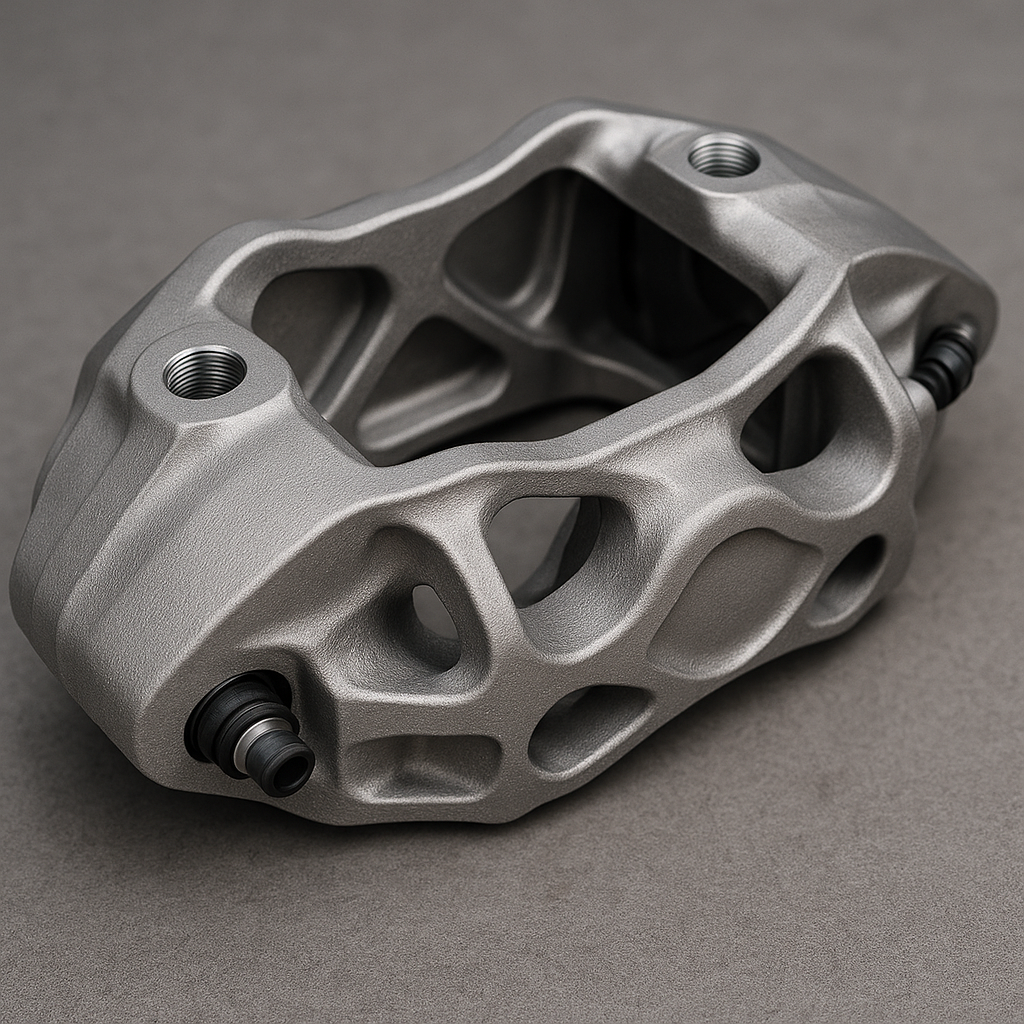

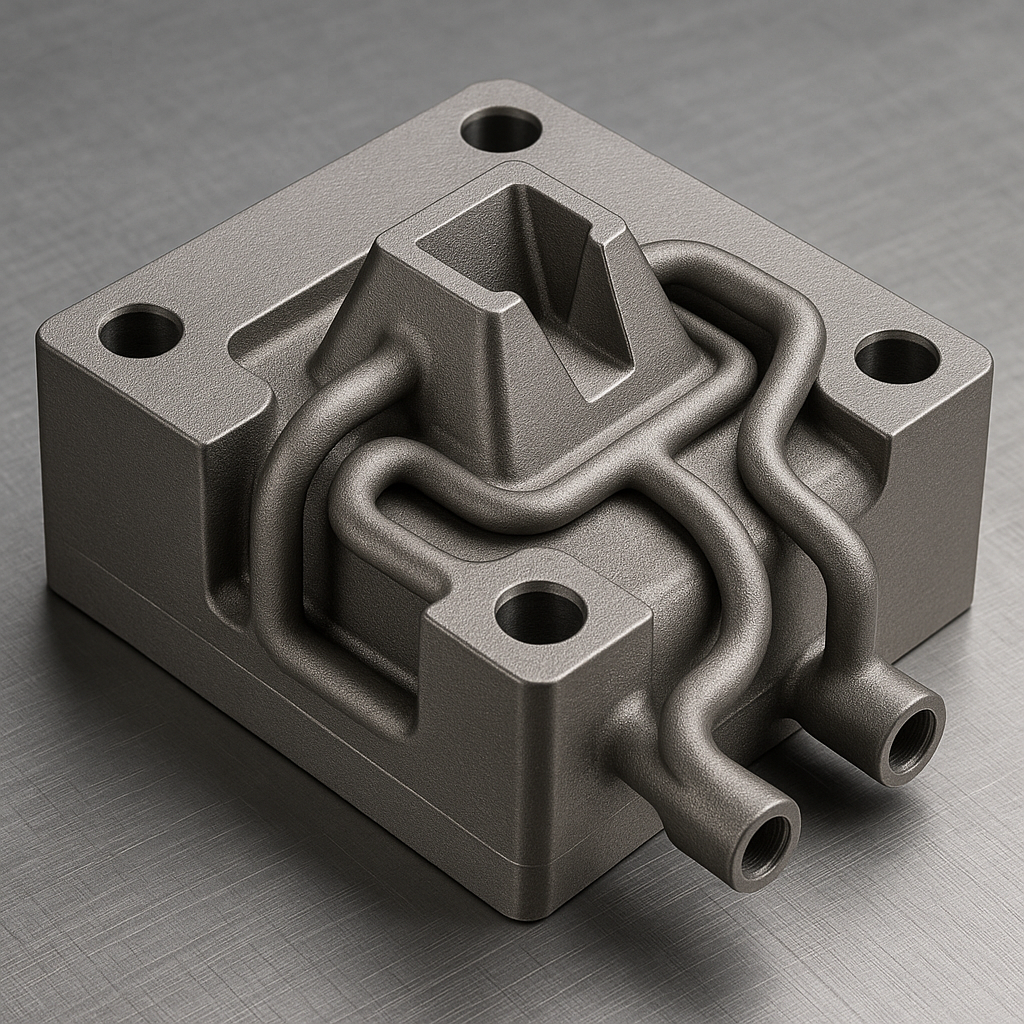

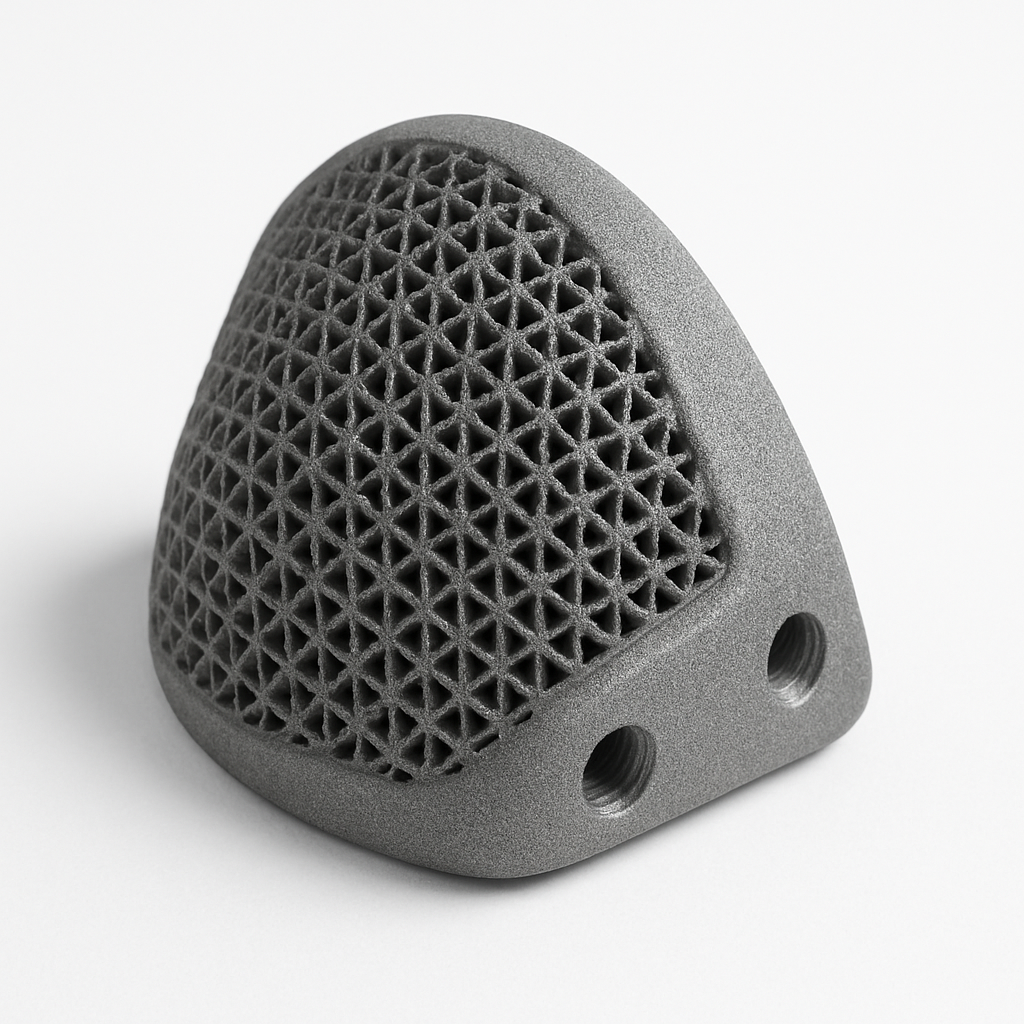

Complex & Lightweight

Designs

Topology optimization, internal channels, and lattice structures are easily achieved—reducing mass without compromising strength.

No Tooling

Required

Ideal for prototyping and low-to-mid volume production, DMLS eliminates the cost and lead time of tooling.