Advantages of MJF 3D Printing

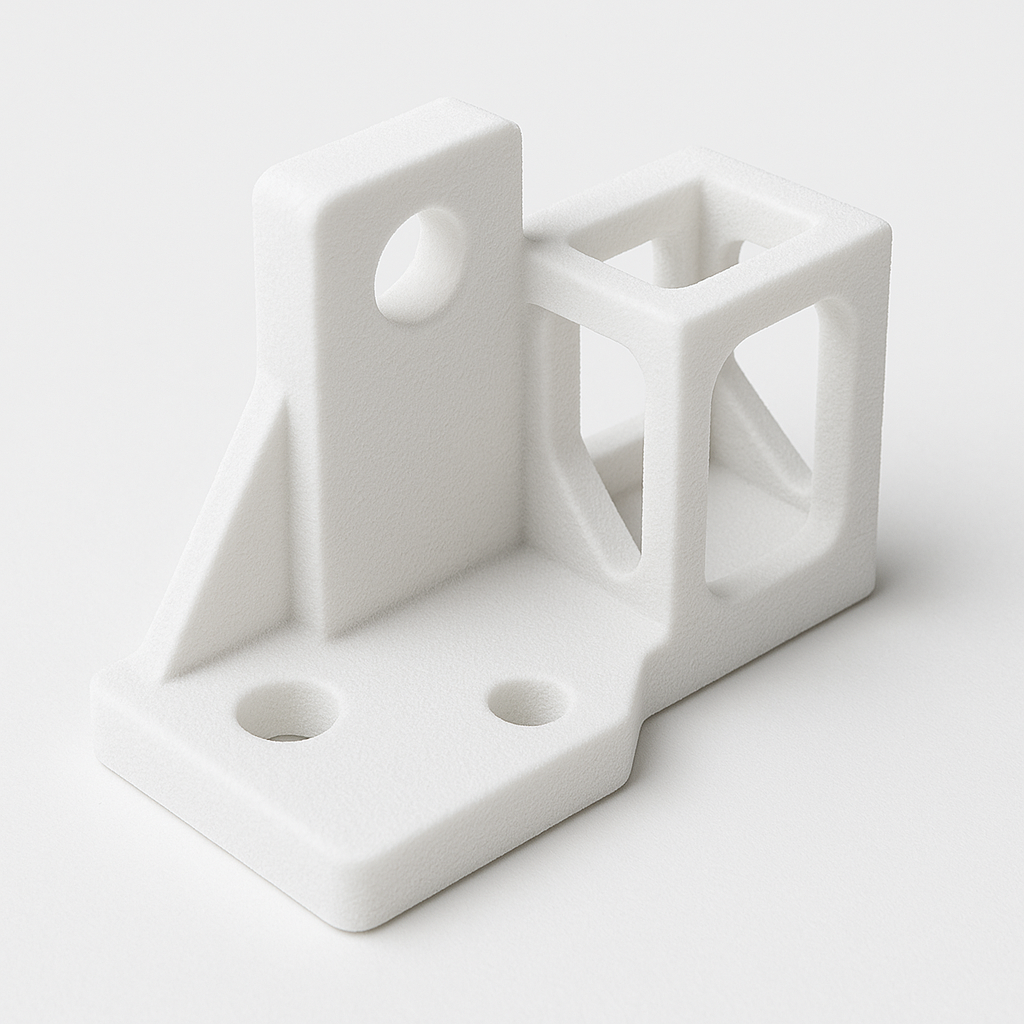

High Mechanical Performance

Finish

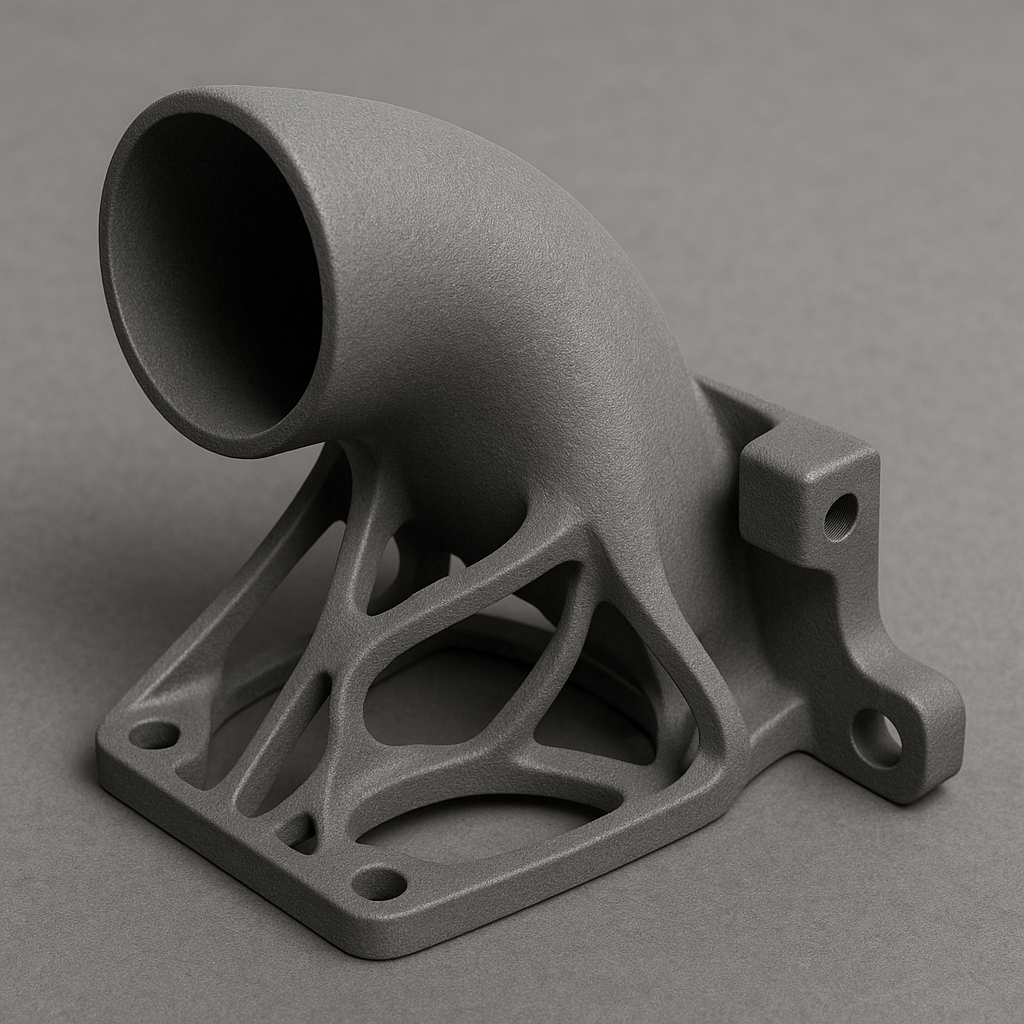

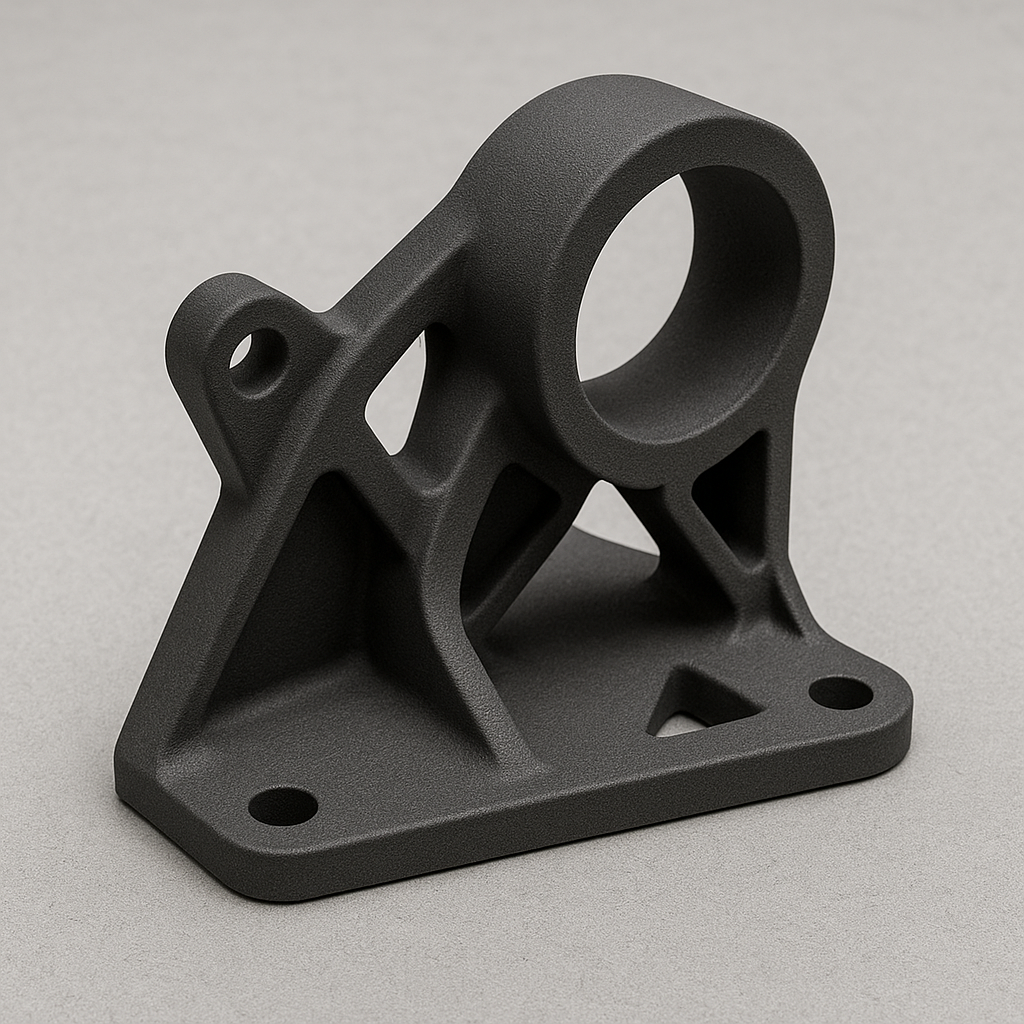

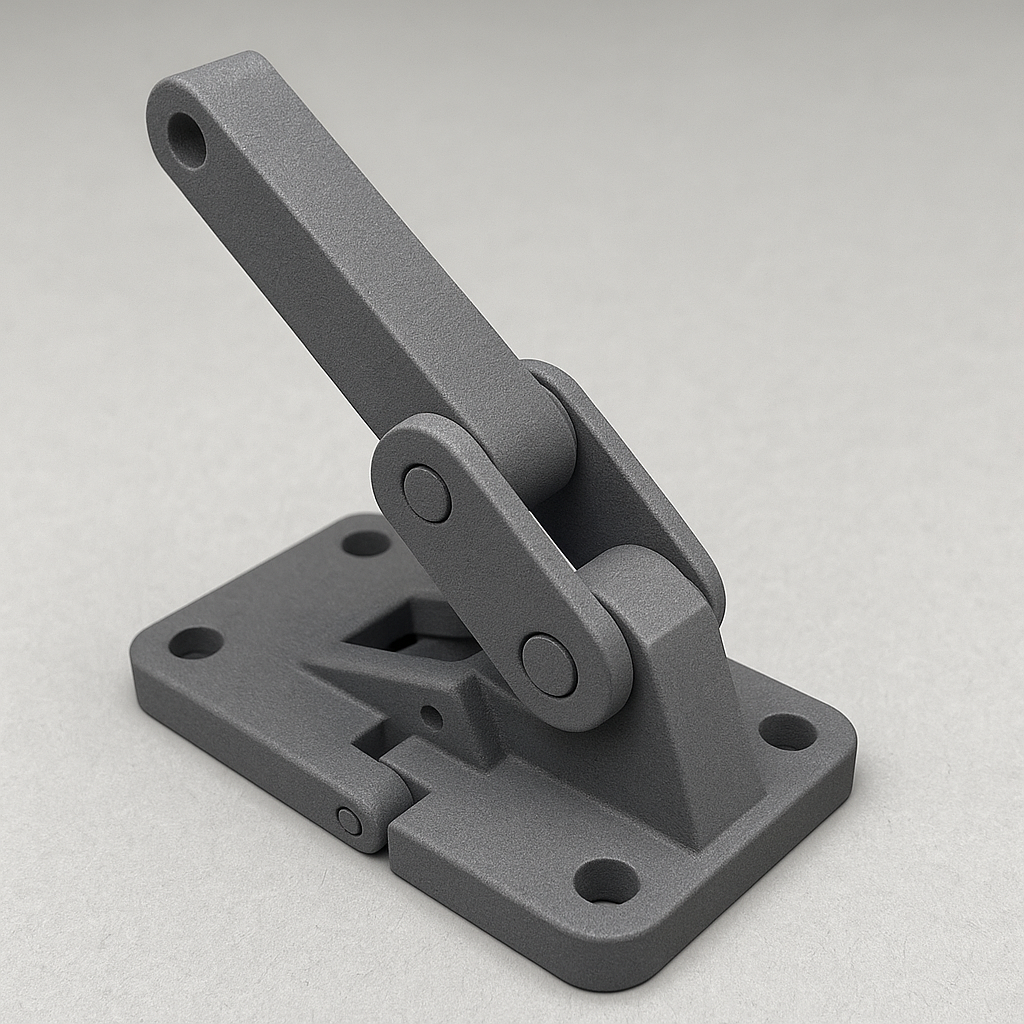

Parts exhibit near-isotropic strength, making them ideal for load-bearing and functional applications.

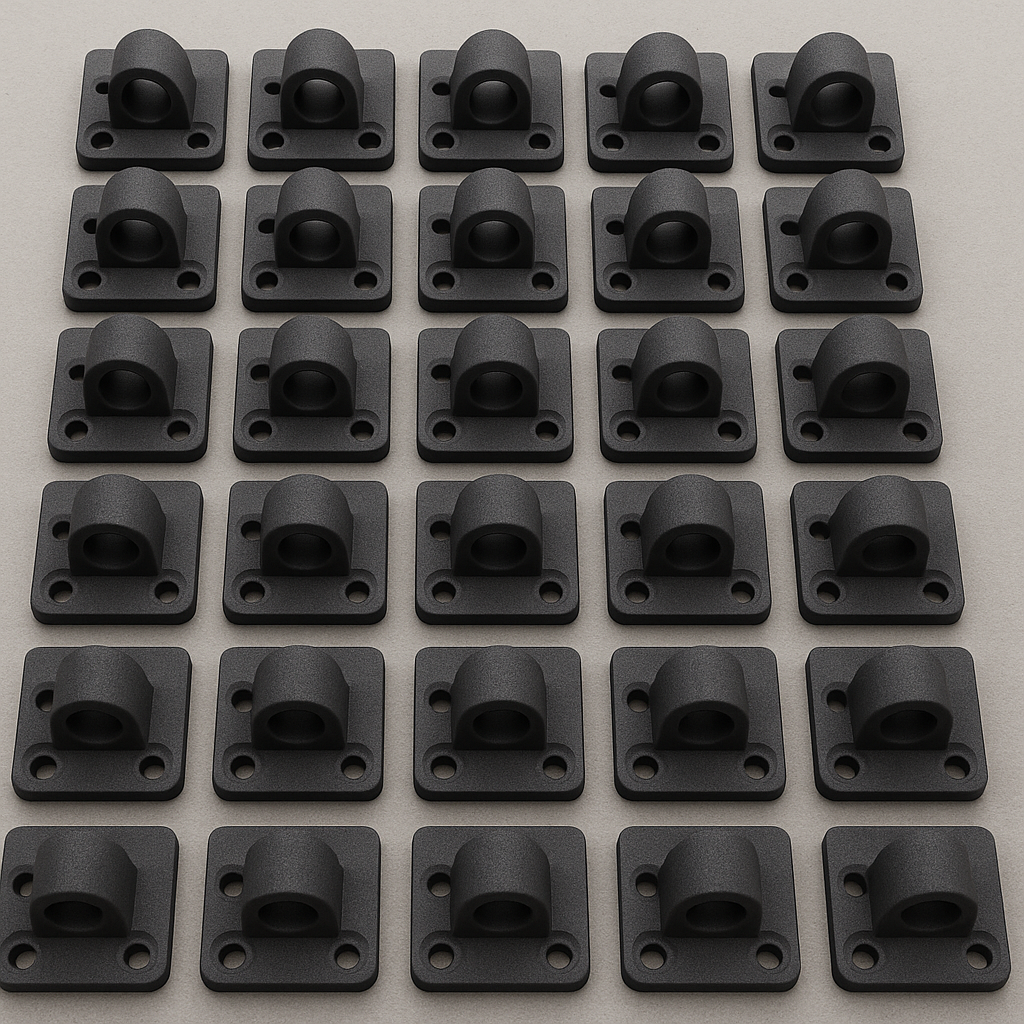

Fast, Scalable Production

High build speeds and nesting efficiency make MJF a powerful tool for both prototyping and production runs.

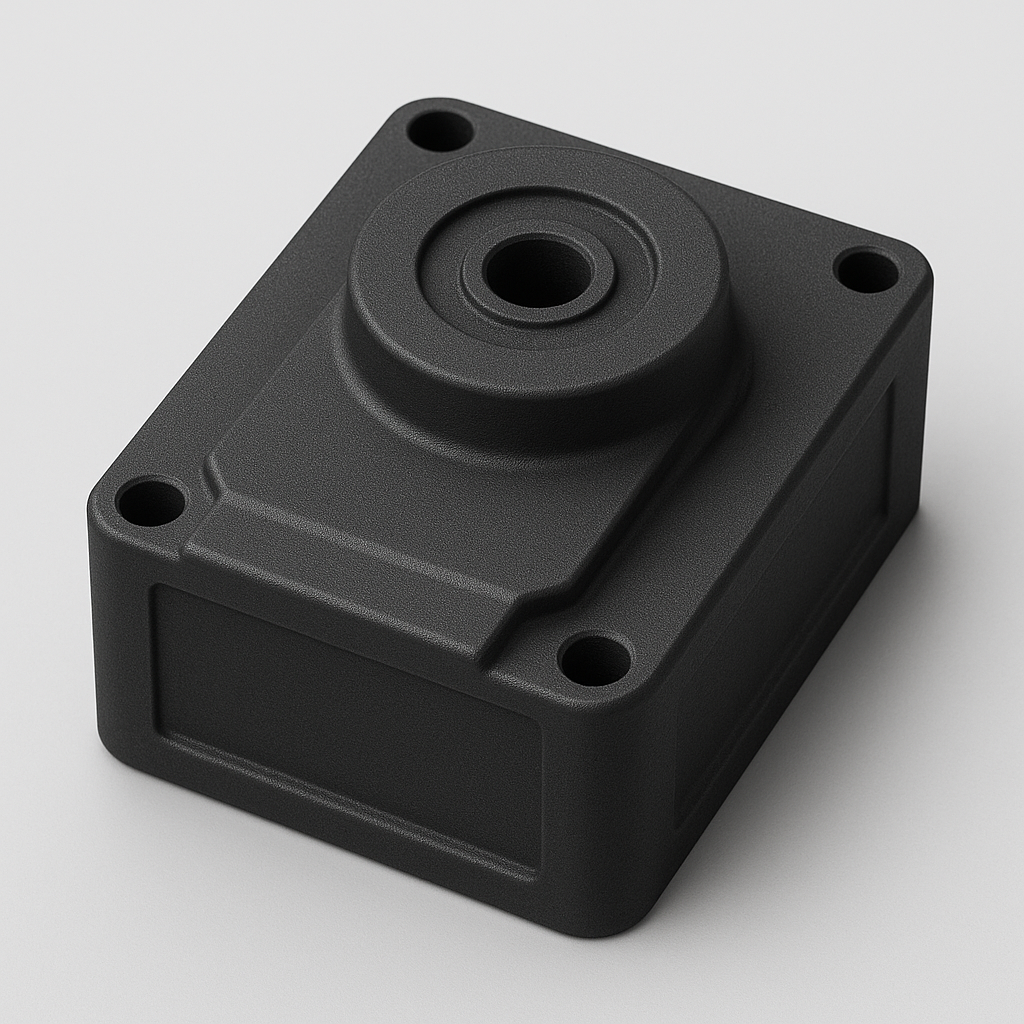

Excellent Surface Finish & Detail

Smooth, uniform surfaces straight off the printer—ideal for consumer-facing and precision-fit components.